Are Electric Plunger Pumps More Efficient Than Diesel-Powered Ones?

As industries worldwide seek to optimize their operations, the question arises: Are electric plunger pumps more efficient than their diesel-powered counterparts?

The Evolution of Plunger Pump Technology

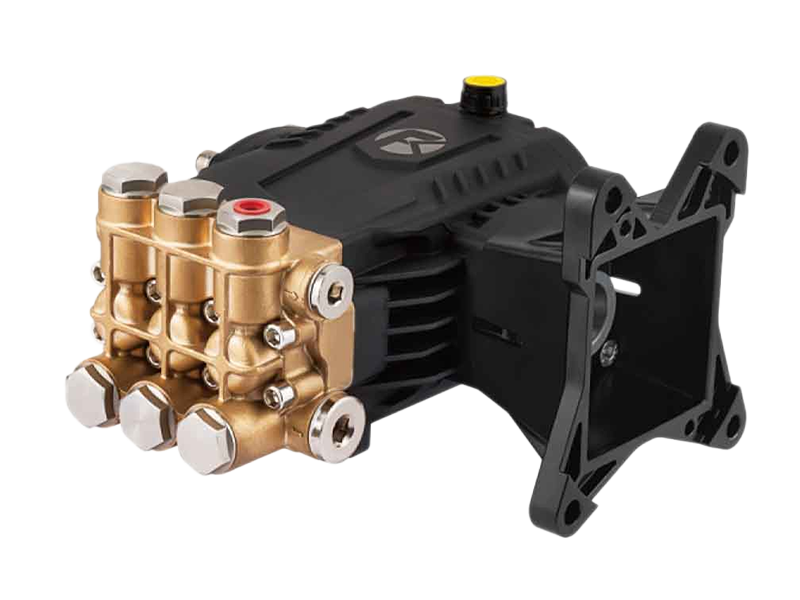

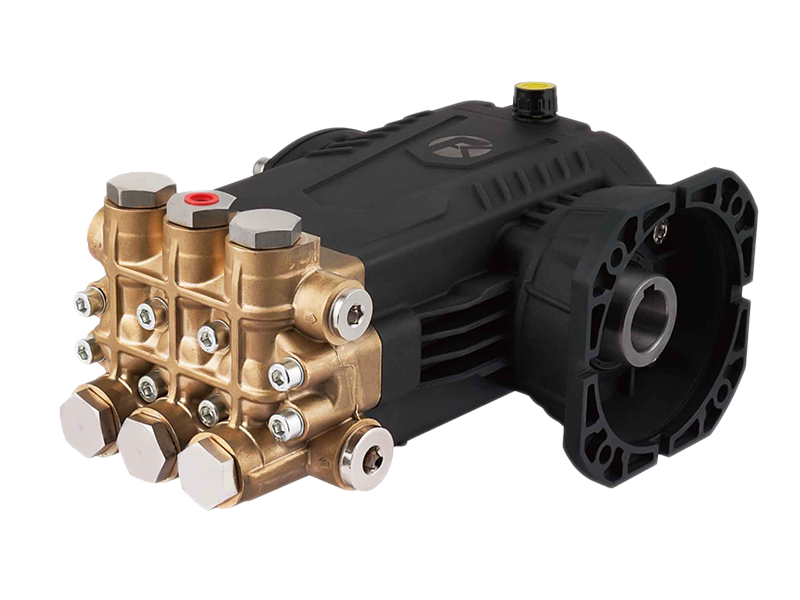

The plunger pump pressure washer, a staple in industries requiring high-pressure fluid applications, has seen a technological shift towards electrification. Traditionally, diesel-powered industrial plunger pumps have been the go-to choice for heavy-duty operations, but the advent of electric plunger pumps has challenged this dominance. Electric plunger pumps, with their silent operation and lower emissions, are now being considered as a more efficient and eco-friendly alternative.

Energy Consumption: A Comparative Analysis

When comparing the energy consumption of electric plunger pumps and diesel-powered industrial plunger pumps, it is clear that electric models have a distinct advantage. Electric plunger pumps are up to 25% more energy efficient than their diesel counterparts, translating to significant savings on energy bills. This efficiency is due to the higher efficiency of electric motors compared to diesel engines, which often have lower energy conversion rates.

Environmental Impact: A Greener Alternative

The environmental impact of industrial operations is a critical concern, and electric plunger pumps offer a greener solution. Diesel-powered industrial plunger pumps emit harmful pollutants, contributing to air and noise pollution. In contrast, electric plunger pumps produce zero emissions at the point of use, aligning with global efforts to combat climate change. This makes them an attractive option for companies committed to reducing their carbon footprint.

Operational Costs: A Financial Perspective

From a financial standpoint, the long-term operational costs of electric plunger pumps are significantly lower. While the initial investment for electric plunger pumps might be higher, the reduced energy consumption and lower maintenance costs mean that the return on investment is often faster. Diesel-powered industrial plunger pumps require regular refueling and maintenance, which can be both costly and time-consuming. Additionally, the fluctuating cost of diesel fuel can cause unpredictable expenses, whereas electricity prices are generally more stable.

Maintenance and Downtime: A Critical Consideration

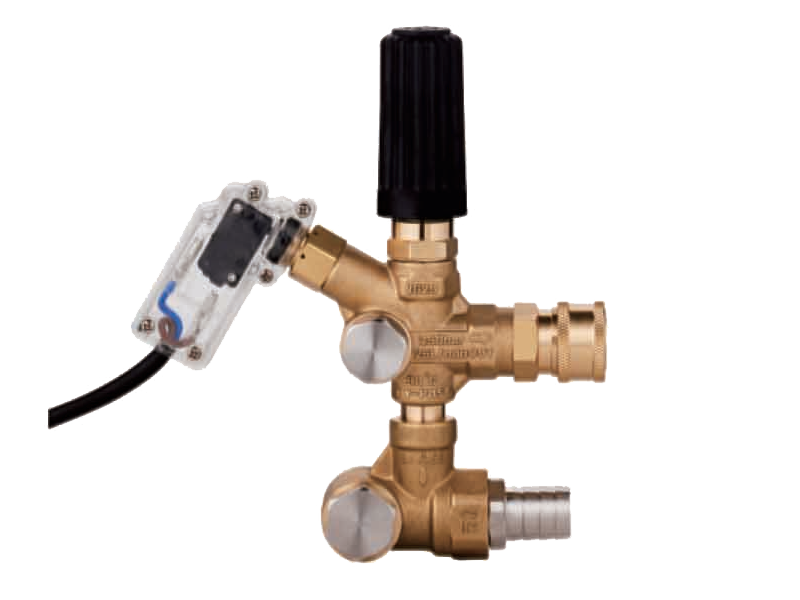

Maintenance is another area where electric plunger pumps excel. Diesel engines are complex, with numerous moving parts that are susceptible to wear and tear, cause frequent breakdowns and costly repairs. Electric plunger pumps, on the other hand, have fewer moving parts and are less prone to mechanical failure, resulting in less downtime and lower maintenance expenses.

Versatility and Application Range

The versatility of electric plunger pumps should not be overlooked. They are compatible with a wide range of applications, from plunger pump pressure washers used in cleaning to industrial processes requiring high-pressure fluid transfer. This adaptability, coupled with their efficiency, makes electric plunger pumps a more attractive option for a diverse range of industries.

The Future of Industrial Pumps

As industries continue to evolve and adapt to new technologies, the trend towards electrification is undeniable. Electric plunger pumps are professional the charge, offering a more efficient, environmentally friendly, and cost-effective solution to traditional diesel-powered industrial plunger pumps. Companies that embrace this shift are poised to reap the benefits in terms of reduced operational costs, improved sustainability, and enhanced productivity.

With the global push towards sustainable practices and the need for cost-effective operations, the electric plunger pump is emerging as the preferred choice for industries worldwide. As technology continues to advance, we can expect to see even more innovative solutions in the realm of industrial plunger pumps, shaping the future of fluid handling and processing.

English

English Español

Español русский

русский