How Stainless Steel Recirculation Pumps Ensure Continuous Flow in Industrial Cooling Systems

Stainless steel recirculation pumps have emerged as the backbone of these systems, providing reliability and efficiency that are unmatched. This article delves into how stainless steel recirculation pumps, stainless steel pressure pumps, and stainless steel gear pumps ensure continuous flow in industrial cooling systems, addressing the key concerns of our clients.

The Crucial Role of Stainless Steel Recirculation Pumps

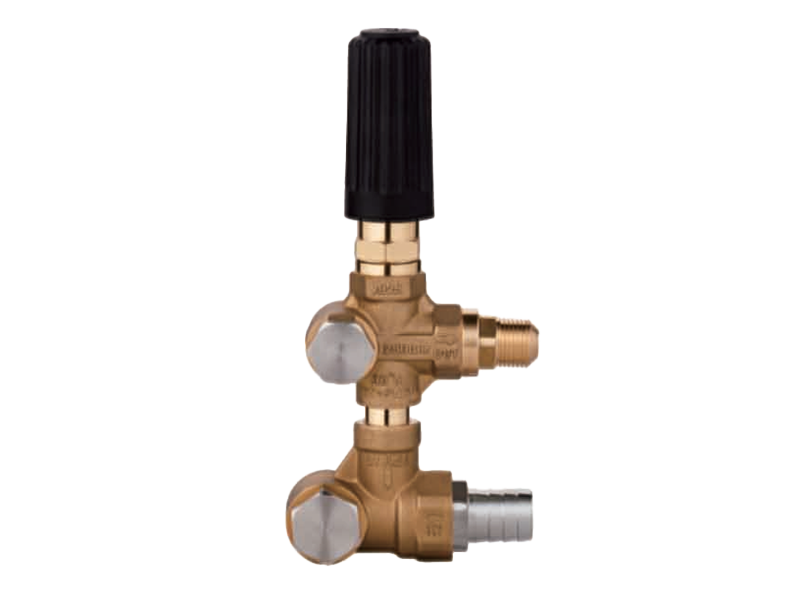

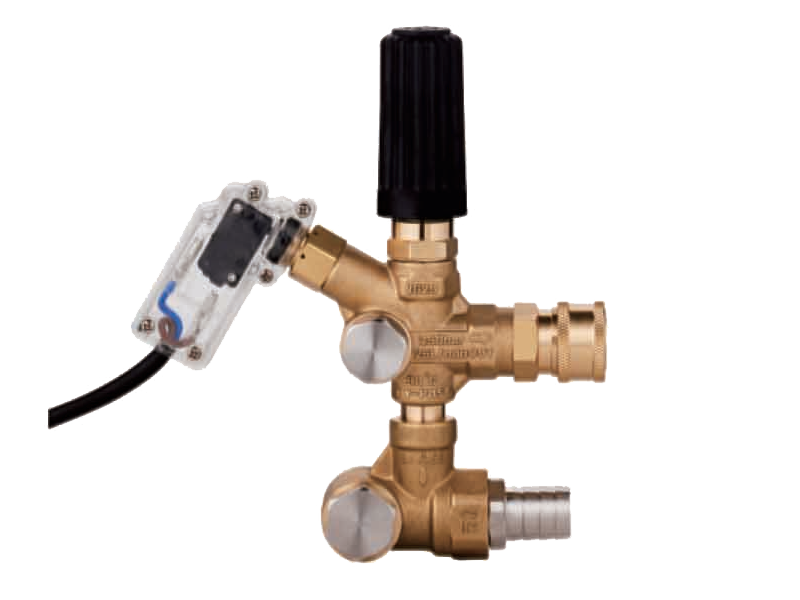

The stainless steel recirculation pump is the heart of any industrial cooling system. These pumps are designed to handle the rigorous demands of circulating coolants, ensuring that the system operates at peak efficiency. The use of stainless steel in the construction of these pumps is not just a matter of aesthetics; it is a strategic choice that offers several benefits.

Durability and Corrosion Resistance: Stainless steel is renowned for its resistance to corrosion, which is a significant advantage in environments where coolants can be corrosive. The stainless steel recirculation pump's ability to withstand such conditions extends its lifespan and reduces maintenance costs, a point of interest for cost-conscious clients.

Consistent Performance: The stainless steel pressure pump is engineered to maintain a consistent flow rate, which is essential for temperature regulation in cooling systems. Fluctuations in flow can cause inefficiencies and potential equipment damage. By providing a steady flow, these pumps help maintain uniform temperatures across the system, ensuring the longevity of the equipment and the quality of the process.

Versatility: Stainless steel gear pumps are not only robust but also versatile, capable of handling a variety of coolants and operating conditions. This adaptability is crucial for industries that require flexibility in their cooling systems, allowing them to switch between different coolants without compromising the integrity of the pump.

Ensuring Continuous Flow

The continuous flow provided by stainless steel recirculation pumps is essential for several reasons:

Preventing Stagnation: Stagnant coolant can cause overheating and potential system failure. The stainless steel recirculation pump's continuous flow prevents this by ensuring that coolant is always circulating, keeping temperatures within the desired range.

Enhancing Heat Transfer: The efficiency of heat transfer in cooling systems is directly related to the flow rate. Stainless steel pressure pumps help maintain an good flow rate, which improves heat transfer and improves the overall cooling efficiency.

Reducing Energy Consumption: By ensuring a consistent flow, stainless steel gear pumps help to minimize energy waste. Pumps that fluctuate in performance can consume more energy as they work harder to compensate for inconsistencies. The reliable performance of stainless steel pumps guides to energy savings and reduced operational costs.

Maintenance and Reliability

One of the primary concerns for clients is the maintenance and reliability of their equipment. Stainless steel recirculation pumps excel in this regard:

Low Maintenance: The stainless steel construction of these pumps means that they are less prone to rust and corrosion, reducing the need for frequent maintenance. This not only saves time but also keeps operational costs low.

Reliability: The stainless steel pressure pump is designed for long-term reliability. It is built to withstand the wear and tear of continuous operation, providing a dependable solution for industrial cooling systems.

Longevity: The stainless steel gear pump's durability means that it can operate for extended periods without failure. This longevity is attractive to clients who seek to minimize downtime and improve the return on their investment.

Conclusion

Stainless steel recirculation pumps, stainless steel pressure pumps, and stainless steel gear pumps have become indispensable in the world of industrial cooling systems. Their ability to ensure continuous flow, durability, and efficiency addresses the primary concerns of clients in the industry. As we look to the future, the role of these pumps will only grow, as industries continue to seek more reliable and efficient ways to manage their cooling systems. The stainless steel recirculation pump stands as a testament to the power of technology and innovation in enhancing industrial operations.

English

English Español

Español русский

русский