Automatic Protection Mechanisms in High-Pressure Pump Systems

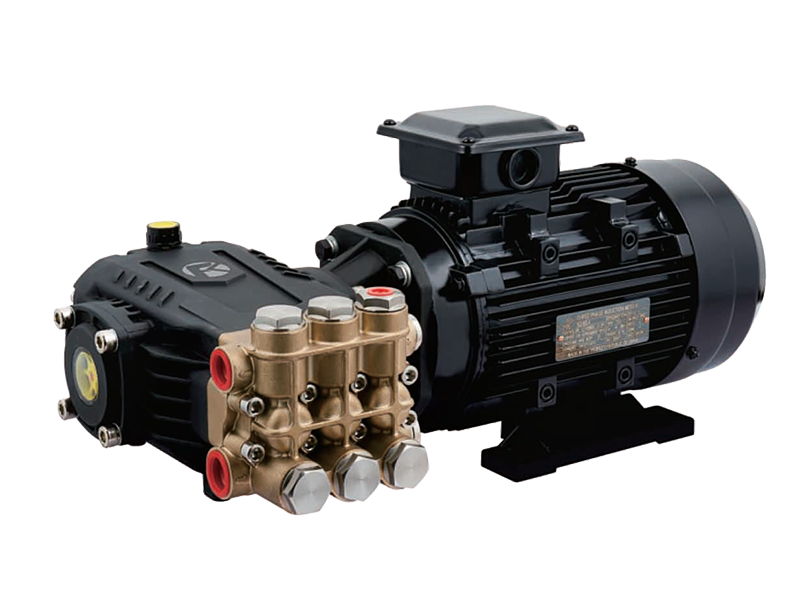

In modern industrial operations, maintaining the stability and safety of high-pressure fluid systems is essential. The Three Plunger High Pressure Pump, known for its ability to deliver continuous and powerful fluid flow, is widely used in fields such as cleaning, descaling, oil extraction, and chemical transfer. However, these systems often operate under extreme conditions, where fluctuations in pressure or mechanical resistance can cause overload or overpressure. Without proper protection mechanisms, these issues can cause component fatigue, seal rupture, or even system failure. Therefore, the question of whether such pumps possess automatic protection systems is crucial to understanding their reliability and long-term performance in demanding environments.

Importance of Protection Systems in High-Pressure Pumps

High-pressure pumps operate by converting mechanical energy into hydraulic energy through reciprocating plungers. When the load or discharge pressure exceeds the pump’s design limit, the stress on internal components increases exponentially. Overpressure can occur due to blockages in discharge lines, sudden valve closures, or misadjustments in the outlet system. Similarly, overload may result from viscosity changes in the pumped medium, increased suction resistance, or prolonged high-demand operation. Without protective control, these conditions can cause mechanical damage or thermal overload. Thus, incorporating automatic protection mechanisms ensures that the pump can respond swiftly to abnormal conditions, safeguarding both the machine and the operator.

Role of Pressure Relief Valves and Safety Devices

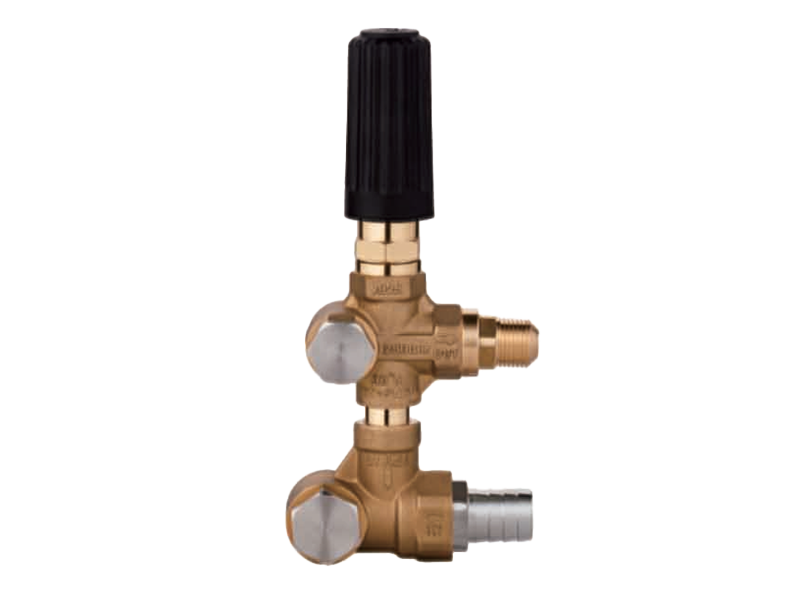

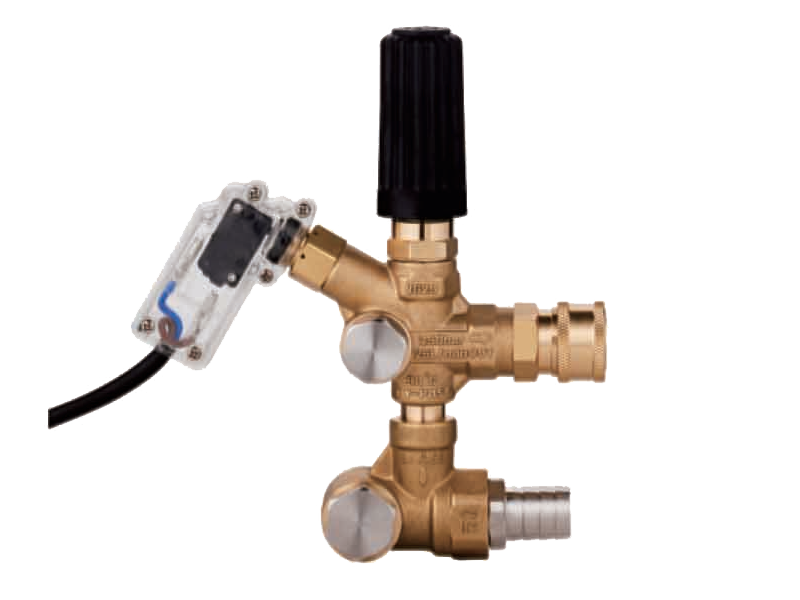

One of the common automatic protection features in a high-pressure system is the pressure relief valve. This device is designed to open automatically when the pressure inside the pump or discharge line exceeds a predefined threshold. By releasing excess pressure, it prevents potential mechanical damage and stabilizes system operation. In advanced designs, the valve may reset automatically once the pressure returns to normal, ensuring continuous performance without manual intervention. Additionally, some systems integrate rupture discs or bypass valves that divert the fluid flow to a return line, effectively reducing overload risks. These mechanical safeguards work together to maintain the pump’s structural integrity during unpredictable pressure surges.

Mechanical Design Features That Prevent Overload

Beyond external control systems, the internal design of a high-pressure pump also plays a crucial role in preventing overload. Components such as crankshafts, connecting rods, and plungers are engineered to distribute force evenly and withstand sudden pressure fluctuations. The pump housing is typically reinforced to contain high-pressure impacts, while the seals and valves are made of materials with good resistance to fatigue and wear. Some models feature hydraulic dampers or accumulator systems that absorb pressure spikes, reducing mechanical stress. Together, these structural features create a self-stabilizing mechanism that enhances the pump’s endurance and reliability under varying load conditions.

Maintenance and Calibration for Reliable Protection

Even with advanced protection systems, regular inspection and calibration are essential to ensure consistent performance. Pressure relief valves must be tested periodically to verify their opening pressure and sealing integrity. Electronic sensors require recalibration to maintain accuracy, especially after long periods of continuous operation. Lubrication, seal replacement, and proper fluid filtration further contribute to stable system behavior. Preventive maintenance not only ensures that automatic protection mechanisms function correctly but also extends the overall lifespan of the equipment, reducing downtime and operational costs.

English

English Español

Español русский

русский