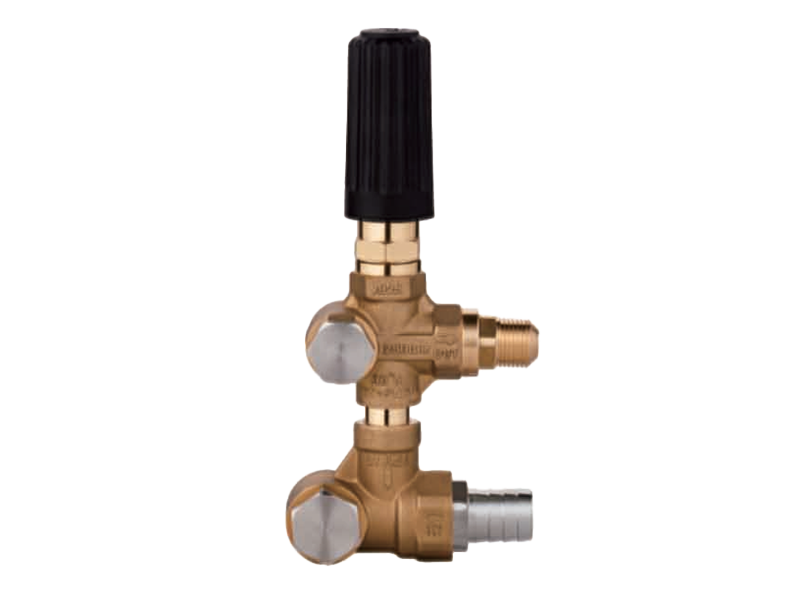

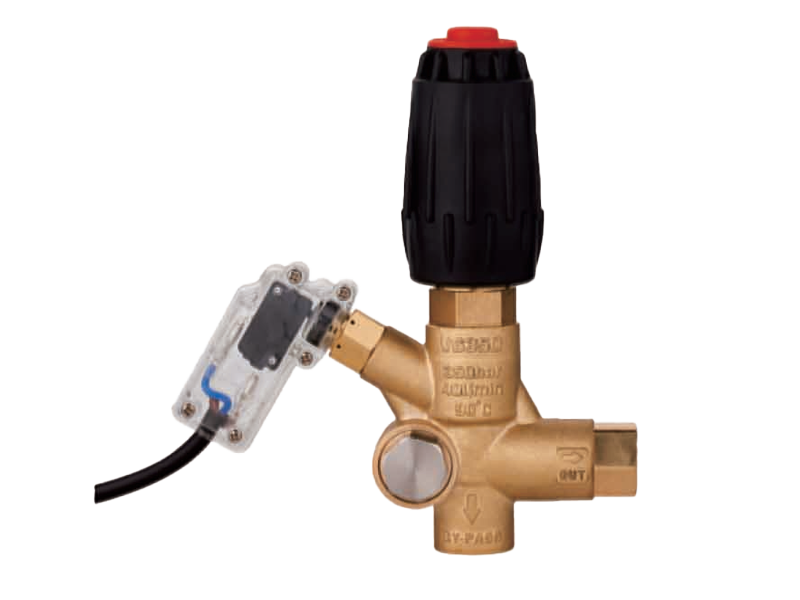

Performance of Three Plunger Pumps in Extreme Conditions

The Three Plunger High Pressure Pump is widely used in industrial applications that demand high pressure and reliability. However, extreme environmental conditions such as high temperature, low temperature, and high humidity can significantly impact pump performance. Understanding how these factors influence operation and whether additional protective measures are required is crucial for maintaining efficiency, longevity, and safety in demanding applications.

High-Temperature Operation

Operating in high-temperature environments can stress the materials and components of a three-plunger pump. Excessive heat may affect seals, gaskets, and lubricants, causing accelerated wear or leakage. Metal components, such as plungers and cylinders, expand at elevated temperatures, which may alter tolerances and reduce volumetric efficiency. To mitigate these issues, specialized high-temperature seals, heat-resistant lubricants, and cooling systems are often recommended. Proper ventilation and placement away from direct heat sources also help maintain suitable performance and prevent overheating.

Low-Temperature Performance

Low temperatures present a different set of challenges for the Three Plunger High Pressure Pump. Cold environments can cause fluids to become more viscous, increasing resistance to flow and requiring greater energy for pumping. Seals and gaskets may become brittle, increasing the risk of cracks and leaks. Additionally, metal components contract at lower temperatures, potentially affecting tolerances and operational smoothness. Preheating the pump, using low-temperature compatible lubricants, and insulating critical components are common protective measures to ensure reliable operation in cold conditions.

High-Humidity Conditions

High humidity introduces the risk of condensation and corrosion, which can damage internal components over time. Moisture can compromise seals, reduce electrical component reliability in motor-driven pumps, and accelerate rust formation on unprotected metal surfaces. For the Three Plunger High Pressure Pump, using corrosion-resistant materials, protective coatings, and sealing electrical parts against moisture ingress is essential. Regular maintenance to remove accumulated moisture and prevent corrosion further extends pump life and maintains operational reliability.

Protective Measures and Practices

In extreme environments, additional protective measures are often necessary to safeguard the pump. These include using stainless steel or coated components for corrosion resistance, installing external insulation or heating jackets in cold conditions, and ensuring adequate ventilation or cooling in high-temperature settings. Choosing lubricants and seals compatible with temperature and humidity extremes is also critical. Environmental enclosures or shelters can provide an added layer of protection against direct exposure to adverse conditions.

Practical Implications for Users

Understanding the specific environmental conditions in which a Three Plunger High Pressure Pump will operate allows users to implement appropriate protective strategies. Failure to account for temperature extremes or high humidity can cause reduced efficiency, increased maintenance, and potential equipment failure. By selecting suitable materials, lubricants, and protective measures, operators can ensure consistent performance, even in harsh industrial settings.

Ensuring Reliable Performance in Harsh Conditions

The Three Plunger High Pressure Pump can perform reliably in high-temperature, low-temperature, and high-humidity environments if appropriate precautions are taken. High-quality materials, compatible lubricants, and protective coatings are essential to mitigate the effects of extreme conditions. Additional measures such as insulation, cooling, or enclosures enhance durability and maintain operational efficiency. Proper planning and preventive maintenance ensure that the pump continues to deliver high-pressure performance safely and efficiently, even under challenging environmental conditions.

English

English Español

Español русский

русский