Selecting Plunger Pump Based on Flow And Pressure

Introduction to Plunger Pump Selection

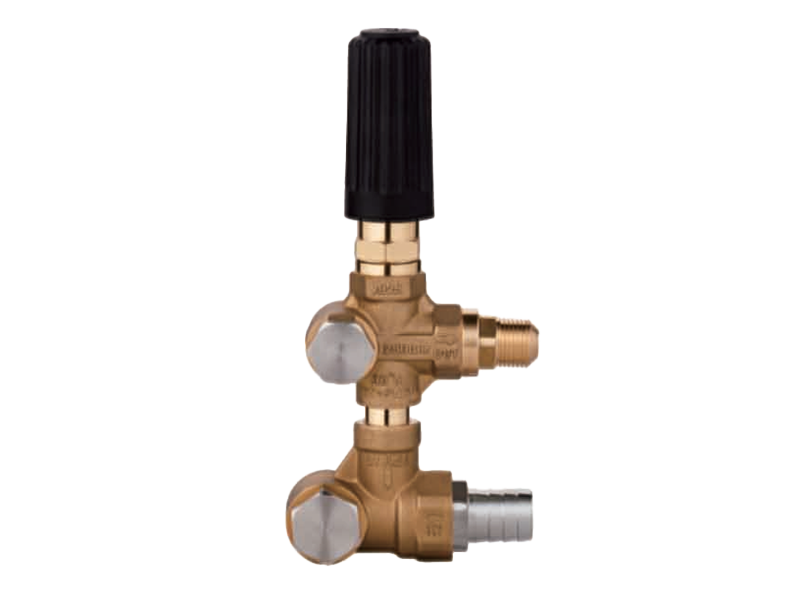

A Plunger Pump is a type of positive displacement pump commonly used in high-pressure applications, including industrial cleaning, chemical processing, and hydraulic systems. Plunger Pump Factory chooses the right plunger pump requires careful consideration of both flow rate and pressure requirements. Selecting an improper pump can cause inefficiency, excessive wear, or even equipment failure.

Understanding Flow Requirements

Flow rate, typically measured in liters per minute (L/min) or gallons per minute (GPM), defines the volume of fluid the pump can move over a specific period. Determining the correct flow rate begins with analyzing the application. For example, in industrial cleaning, the pump must provide sufficient water volume to cover the target area efficiently. In chemical injection systems, precise flow control ensures proper dosing. Overestimating flow can result in wasted energy and higher operating costs, while underestimating it can cause insufficient process performance and reduced productivity.

Evaluating Pressure Needs

Pressure, measured in bar or psi, represents the force the pump can exert on the fluid. The required pressure is determined by system resistance, such as pipe length, diameter, fittings, and nozzle or valve requirements. High-pressure applications, like water jet cleaning or hydraulic testing, demand pumps capable of maintaining consistent pressure under load. Choosing a pump with insufficient pressure can cause inadequate performance and process inefficiency, whereas selecting a pump with excessive pressure may cause unnecessary wear on system components or safety risks.

Matching Flow and Pressure Specifications

The important step in selecting a plunger pump is finding a model that meets both flow and pressure requirements simultaneously. Pump performance curves provided by manufacturers illustrate the relationship between flow and pressure for each model. Reviewing these curves allows users to select a pump that operates efficiently at the desired point. It is crucial to account for variations in system demand, ensuring the pump can handle peak loads without exceeding its rated specifications.

Material and Design Considerations

Flow and pressure are not the only factors to consider. The fluid type, temperature, and chemical compatibility influence material selection and pump design. Stainless steel or other corrosion-resistant materials are often required for aggressive chemicals, while durable seals and plungers ensure longevity under high-pressure conditions. Choosing a high-quality pump from a reputable Plunger Pump Factory guarantees that the materials and design meet industry standards and application demands.

Maintenance and Safety Factors

Selecting a pump that matches flow and pressure needs also simplifies maintenance and enhances safety. A properly sized pump reduces excessive wear on plungers, valves, and seals, reducing downtime. Operators should consider accessibility for routine inspections, lubrication requirements, and potential safety risks associated with high-pressure operation. Adhering to manufacturer recommendations ensures that the pump performs reliably and safely over its service life.

Selecting the right plunger pump requires careful analysis of both flow and pressure requirements, along with consideration of fluid type, system design, and material compatibility. Evaluating manufacturer performance curves, choosing durable construction, and following practices for maintenance and safety ensure that the pump operates efficiently and reliably. Working with a trusted Plunger Pump Factory helps users identify the suitable pump model, reducing operational risks and improving long-term performance across various industrial applications.

English

English Español

Español русский

русский