Can a Commercial Electric Power Washer Handle Oil and Grease Removal?

For businesses in automotive, manufacturing, and food service, oil and grease buildup is a constant challenge. Many assume only gas-powered or steam cleaners can tackle these tough jobs—but modern commercial electric power washer models are proving otherwise. With advancements in motor efficiency and pressure technology, today's powerful electric power washer units can compete with traditional alternatives while offering quieter operation, zero emissions, and lower maintenance.

The Oil and Grease Cleaning Challenge

Removing oil and grease requires a combination of:

- High Pressure (1,500–3,000+ PSI): To penetrate and lift stubborn residues.

- Hot Water (Optional): Heat breaks down grease faster than cold water alone.

- Chemical Compatibility: Detergents designed to emulsify oils.

While gas-powered commercial power washer systems have long dominated this space, electric models are closing the gap.

How Electric Models Stack Up

A powerful electric power washer designed for commercial use offers several advantages for grease removal:

1. Precision Pressure Control

- Unlike gas engines that run at fixed RPMs, electric motors allow variable speed adjustments. This lets operators dial in the exact pressure needed—critical for avoiding surface damage while still blasting away grease.

2. Hot Water Electric Units

- Some commercial electric power washer systems now integrate heating elements, producing water temps up to 140°F (60°C). This matches the performance of many gas-powered hot water cleaners.

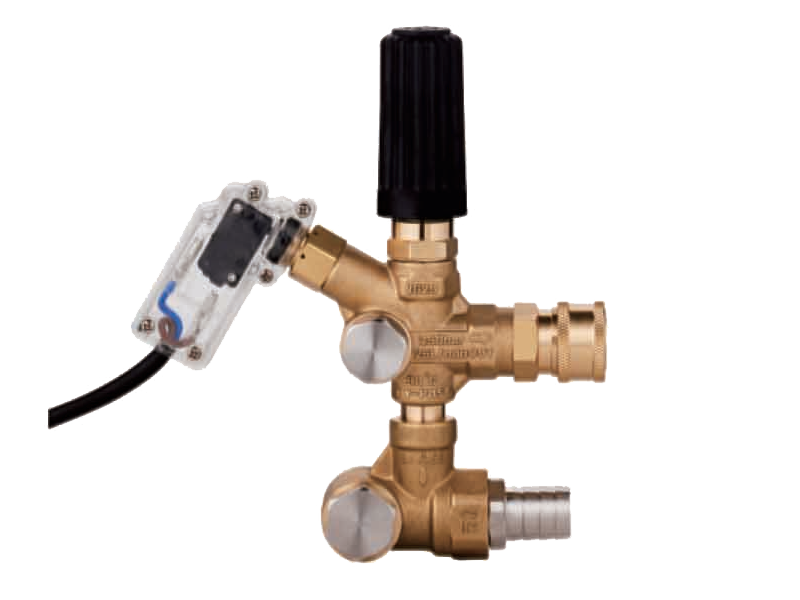

3. Chemical Injection Systems

- Built-in detergent tanks in professional-grade commercial power washer models allow for direct application of degreasers. Electric pumps maintain consistent chemical ratios better than pulsating gas systems.

Real-World Applications

Industries successfully using powerful electric power washer units for oil/grease removal include:

- Auto Shops: Degreasing engine bays without fumes (ideal for indoor use).

- Food Processing: Cleaning fryer hoods and conveyor belts where gas exhaust is prohibited.

- Warehouses: Maintaining forklifts and loading docks in enclosed spaces.

A commercial electric power washer with 2,200+ PSI and heated water can often replace gas models in these scenarios.

Limitations to Consider

While improving, electric models still have some constraints:

- Power Requirements: Most commercial power washer units need 220V outlets for full performance.

- Runtime: Continuous heavy use may require pauses to prevent motor overheating.

- Grease Buildup: Multi-year industrial sludge may still need steam or higher-PSI gas units.

However, for 80% of commercial grease cleaning tasks, a powerful electric power washer now provides adequate power with added convenience.

Choosing the Right Electric Model

Key specs to look for in a commercial electric power washer for oil/grease:

- Minimum 2,000 PSI/2.0 GPM: Below this struggles with heavy buildup.

- Thermal Safety Cutoffs: Prevents damage during prolonged use.

- Certified Degreaser Compatibility: Not all electric pumps handle harsh chemicals well.

Brands like Kärcher, Mi-T-M, and AR Blue Clean now offer commercial power washer systems specifically designed for grease removal.

Maintenance Advantages Over Gas

A powerful electric power washer typically requires less upkeep than gas counterparts:

- No spark plugs, oil changes, or carburetor cleanings.

- Fewer vibrations reduce hose/connection wear.

- Instant starts eliminate pull-cord frustrations.

This makes the commercial electric power washer a cost-effective long-term solution.

The Future of Electric Industrial Cleaning

As battery technology improves, cordless commercial power washer models are emerging for complete portability. Meanwhile, 3-phase electric units now rival gas-powered 4,000 PSI systems for heavy industrial use.

Today's powerful electric power washer models can absolutely handle most commercial oil and grease removal tasks—with significant operational benefits. While cases may still require gas or steam, a properly specified commercial electric power washer delivers eco-friendly, low-maintenance cleaning power for workshops, factories, and food service environments. As electric motor technology continues advancing, these systems will only become more capable of replacing traditional grease-fighting equipment.

English

English Español

Español русский

русский