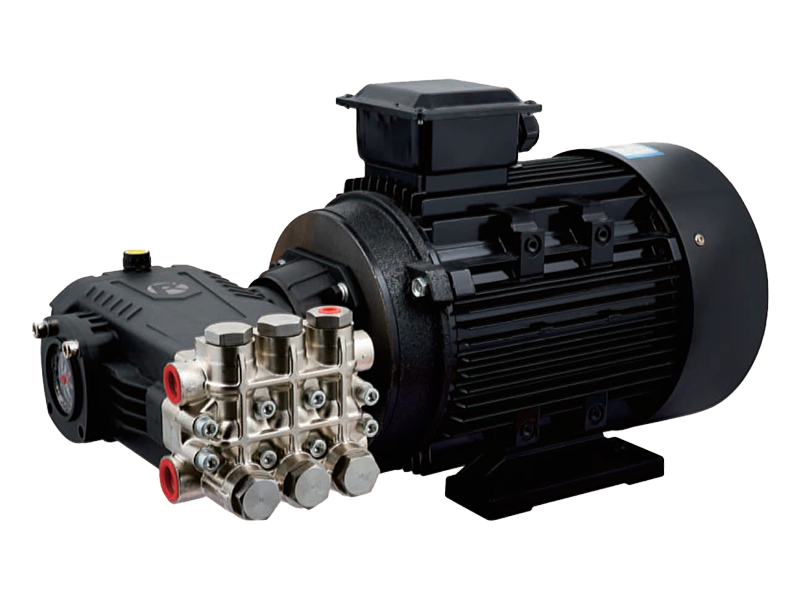

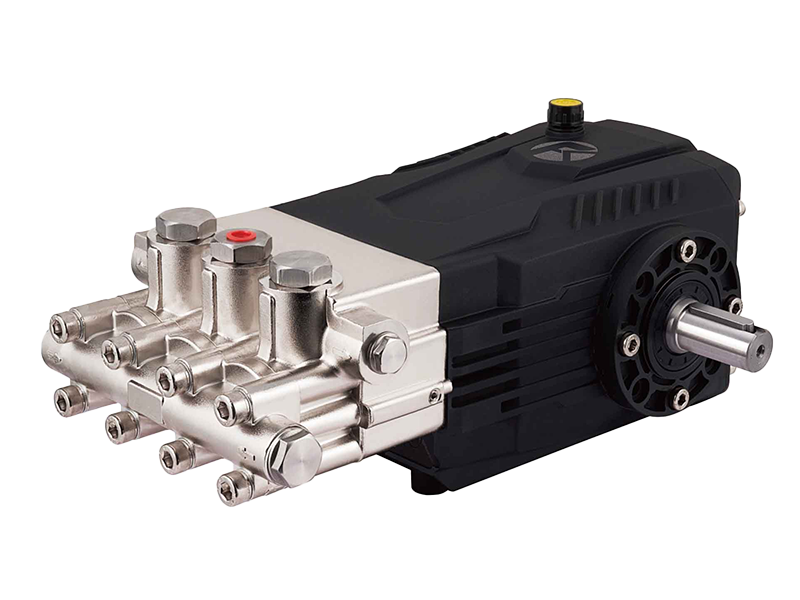

How to Prevent Cavitation in Horizontal Triplex Pumps for Longer Lifespan?

Cavitation is a significant concern for operators of horizontal triplex pumps, as it can cause reduced efficiency, increased maintenance costs, and shortened pump lifespan. Cavitation occurs when vapor bubbles form and collapse within the pump, causing mechanical damage and operational inefficiencies. However, by understanding the causes and implementing effective prevention strategies, you can significantly extend the lifespan of your triple piston pump and maintain good performance.

Understanding Cavitation in Horizontal Triplex Pumps

Cavitation in horizontal triplex pumps typically occurs when the local pressure within the pump drops below the vapor pressure of the liquid being pumped. This pressure drop can cause the formation of vapor bubbles, which then collapse as they enter higher-pressure regions, causing shock waves that erode pump components. Common causes of cavitation include insufficient Net Positive Suction Head (NPSH), high fluid temperatures, excessive pump speeds, and flow restrictions.

Key Strategies to Prevent Cavitation

1. Ensure Adequate NPSH

One of the primary factors in preventing cavitation is maintaining sufficient NPSH. The available NPSH must exceed the pump's required NPSH to prevent vapor bubble formation. This can be achieved by:

- Optimizing Suction Line Design: Use short, direct suction piping with minimal bends and ensure the pipe diameter is large enough to reduce fluid velocity and friction losses.

- Maintaining Fluid Levels: Ensure the pump inlet is properly submerged to prevent air entrainment, which can cause cavitation.

2. Control Operating Conditions

Monitoring and controlling the operating conditions of your horizontal triplex pump is crucial in preventing cavitation. This includes:

- Managing Fluid Temperature: High fluid temperatures can lower the liquid's vapor pressure, making it more susceptible to cavitation. Ensure that the fluid temperature is within the recommended range.

- Regulating Pump Speed: Operating the pump at excessive speeds can reduce suction pressure and increase the risk of cavitation. Using variable frequency drives (VFDs) can help maintain good operating speeds.

3. Implement Anti-Cavitation Devices

Installing anti-cavitation devices can significantly reduce the risk of cavitation in horizontal triplex pumps. These devices include:

- Inducers: Adding an inducer to the pump inlet can pre-pressurize the liquid, increasing the inlet pressure and reducing the likelihood of vapor bubble formation.

- Flow Straighteners and Diffusers: These devices help to distribute flow evenly, reducing turbulence and pressure fluctuations at the pump inlet.

4. Regular Maintenance and Inspection

Regular maintenance is essential in identifying and addressing potential cavitation issues early. Key maintenance practices include:

- Scheduled Inspections: Periodically inspect the pump components, such as impellers and casings, for signs of erosion or damage caused by cavitation.

- Cleaning and Debris Removal: Regularly clean the pump to remove any accumulated debris that could disrupt flow and cause pressure fluctuations.

- Component Replacement: Replace worn or damaged components promptly to maintain good performance and prevent cavitation.

5. Proper Pump Selection and Installation

Choosing the right pump for your application and ensuring proper installation are foundational steps in preventing cavitation. Consider the following:

- Selecting the Right Pump: Ensure the pump is suitable for the specific application, taking into account factors such as flow rate, pressure requirements, and fluid properties.

- Accurate Installation: Properly align the pump and driver shafts, secure the pump on a stable foundation, and design the piping to minimize turbulence and pressure drops.

Preventing cavitation in horizontal triplex pumps is essential for maintaining their efficiency and extending their lifespan. By ensuring adequate NPSH, controlling operating conditions, implementing anti-cavitation devices, and adhering to regular maintenance practices, you can significantly reduce the risk of cavitation. Proper pump selection and installation also play a crucial role in creating a stable and efficient operating environment.

By following these strategies, operators of horizontal triplex pumps can enjoy reliable performance and reduced maintenance costs, making their equipment more efficient and cost-effective in the long run.

English

English Español

Español русский

русский