Choose Between Stainless Centrifugal Pumps and Booster Pumps for Specific Industrial Needs

When selecting the right pump for your industrial applications, it's essential to understand the differences and advantages of various pump types. Each of these pumps serves distinct purposes and is designed to handle specific tasks, which makes choosing the right one crucial to optimizing performance and ensuring long-term reliability.

Stainless centrifugal pumps are commonly used in industries that require continuous fluid movement, such as water treatment, food processing, and chemical manufacturing. These pumps operate by converting rotational kinetic energy, usually from an electric motor, into fluid energy. The pump uses a rotating impeller to increase the velocity of the liquid, which is then directed into a discharge pipe. The primary advantage of a stainless centrifugal pump is its ability to handle large volumes of liquids efficiently, making it suitable for low to medium pressure applications.

A stainless centrifugal pump is highly effective when dealing with clean, non-viscous fluids such as water, oils, or light chemicals. It is especially advantageous in applications where the fluid needs to be moved over long distances, and a steady flow is essential. Because of its simplicity and cost-effectiveness, this type of pump is often the preferred choice in many industries.

However, stainless centrifugal pumps do have limitations. They are not ideal for high-pressure applications or for pumping thick liquids like sludge or heavy oils. In cases where pressure boosting or high flow is needed, other pump types may be a better fit.

On the other hand, stainless booster pumps are designed specifically for applications that require increased pressure to push fluids through a system. These pumps are often used in settings where water pressure needs to be increased for specific tasks, such as in irrigation systems, HVAC, or for boosting water pressure in residential and commercial buildings. Stainless booster pumps are particularly useful for scenarios where water needs to be pumped to higher elevations or where the pressure in a pipeline needs to be maintained for efficient system performance.

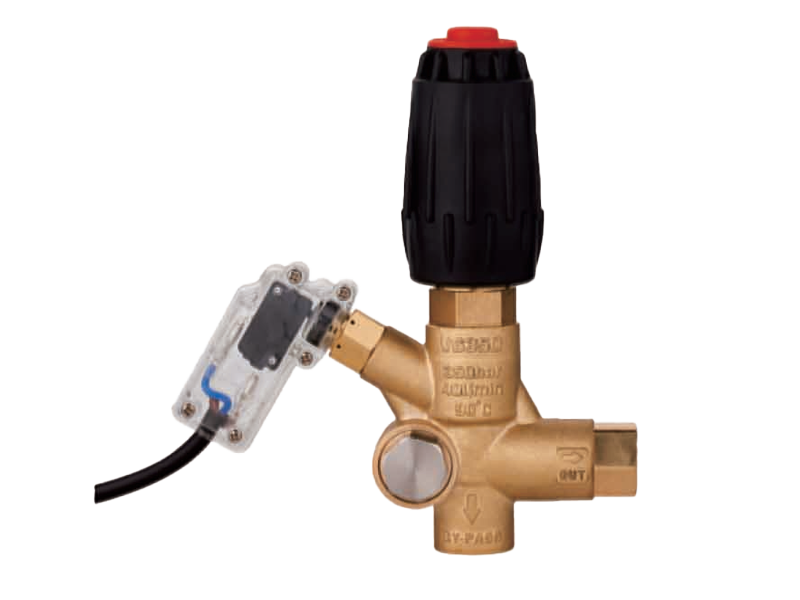

A stainless booster pump works by boosting the pressure of the incoming water or liquid before it is pushed into a pipeline or other system. This is achieved by incorporating a pump that increases the fluid's pressure while maintaining a steady flow. These pumps are often paired with pressure switches or variable frequency drives to maintain good pressure levels.

In contrast to stainless centrifugal pumps, which focus on continuous flow, stainless booster pumps are better suited for applications where pressure is the key requirement. They are ideal for systems with fluctuating pressure demands or where consistent and reliable pressure is needed for high-rise buildings, industrial processes, or fire suppression systems.

Stainless Steel Chemical Pumps

When handling aggressive chemicals, such as acids, solvents, or other corrosive materials, stainless steel chemical pumps are option. These pumps are built with corrosion-resistant stainless steel components, ensuring durability and longevity even when exposed to harsh environments. Stainless steel chemical pumps are used in industries such as pharmaceuticals, chemical processing, and wastewater treatment, where the pump needs to withstand corrosive substances while maintaining performance.

A stainless steel chemical pump can be either centrifugal or diaphragm-based, depending on the specific needs of the application. These pumps are engineered to handle a wide range of chemicals without degrading or corroding, which is crucial when dealing with substances that could damage standard pump materials. Additionally, stainless steel chemical pumps are often equipped with seals and gaskets that are resistant to chemical attacks, ensuring reliable operation even in demanding conditions.

Choosing the Right Pump for Your Needs

When deciding between a stainless centrifugal pump, stainless booster pump, or stainless steel chemical pump, it is essential to consider the specific needs of your industrial application. For example, if your system requires high flow and relatively low pressure, a stainless centrifugal pump is a great choice. These pumps are easy to maintain, highly efficient, and ideal for transporting clean fluids.

English

English Español

Español русский

русский