What Makes Air Power Washers a Safe and Efficient Cleaning Solution for Industrial Use?

Traditional cleaning methods often fall short when dealing with heavy grease, oil, or stubborn debris in factories, warehouses, and construction sites. This is where air power washers excel—offering a powerful yet controlled cleaning solution that outperforms many conventional systems.

The Advantages of Air Power Washers in Industrial Settings

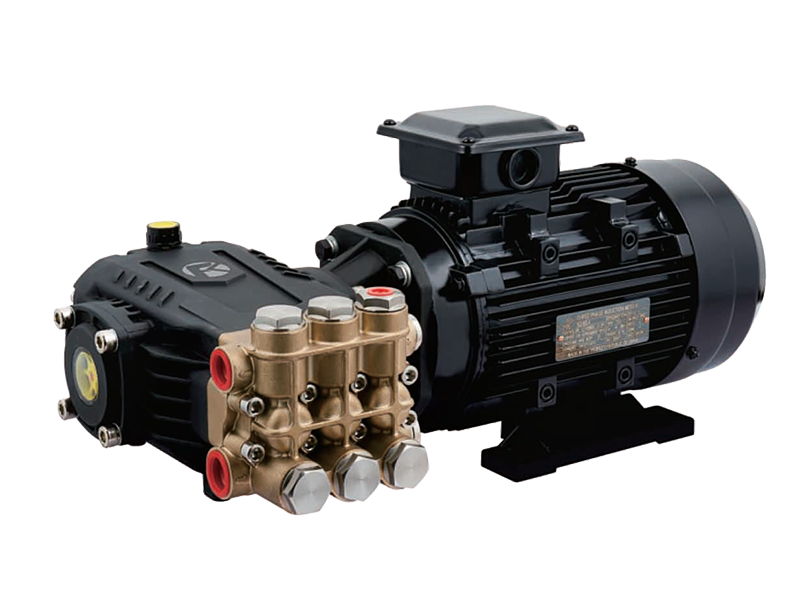

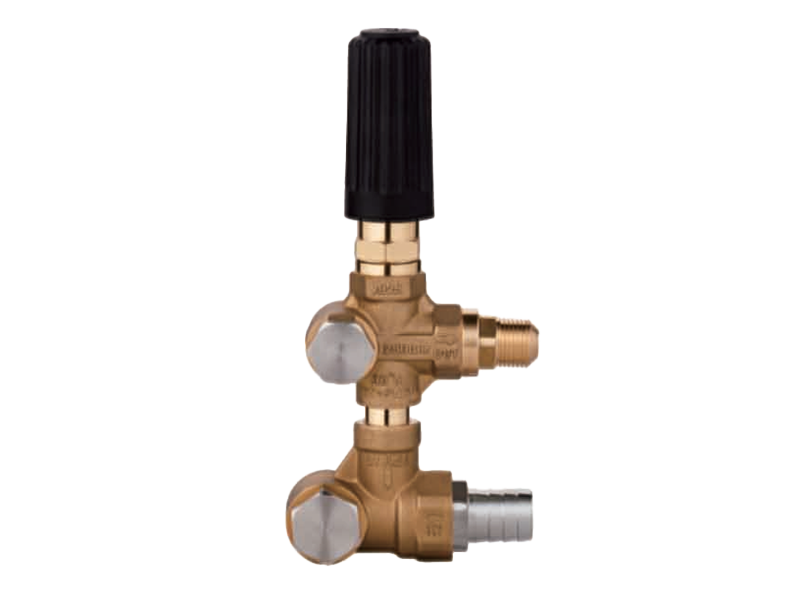

One of the biggest benefits of an air power washer is its ability to deliver high-pressure cleaning without the force of traditional systems. Standard power water washers rely solely on hydraulic pressure, which can sometimes damage sensitive equipment or surfaces. In contrast, air power washers use compressed air to regulate pressure, allowing operators to adjust intensity based on the task. This makes them ideal for cleaning machinery, vehicle fleets, and production lines where precision matters.

Another key advantage is safety. Because air power washers don't rely on electric motors near water sources, they reduce the risk of electrical hazards. Many industrial-grade models also feature water cooled pressure washer technology, which prevents overheating during extended use. This cooling mechanism ensures consistent performance while extending the machine's lifespan—a critical factor in high-volume cleaning operations.

How Air Power Washers Compare to Traditional Systems

When evaluating cleaning solutions, many facilities default to standard power water washers due to their widespread availability. However, these systems have limitations. They often produce excessive pressure, cause surface damage or unnecessary water consumption. An air power washer, on the other hand, provides more control, allowing operators to fine-tune pressure levels for different materials—from delicate electronics to heavily soiled concrete.

Additionally, water cooled pressure washer integration in some air power washer models enhances efficiency. Traditional systems can overheat during prolonged use, cause downtime. A water cooled pressure washer design dissipates heat more effectively, making it ideal for shift-long cleaning tasks in manufacturing plants or food processing facilities.

Key Applications in Industrial Cleaning

Industries that benefit most from air power washers include:

- Manufacturing: Removing grease, metal shavings, and coolant residues from equipment.

- Transportation: Degreasing engines, truck beds, and aircraft components without damaging surfaces.

- Food Processing: Sanitizing production lines where chemical or steam cleaning isn't feasible.

- Construction: Clearing debris from tools and heavy machinery in remote job sites.

In each case, the adjustable pressure of an air power washer ensures thorough cleaning without the risks associated with conventional power water washers.

Maintenance and Longevity Considerations

One reason industries are shifting toward air power washers is their durability. Since they operate with compressed air rather than relying solely on high-pressure water pumps, they experience less wear and tear. Models equipped with water cooled pressure washer technology further reduce maintenance needs by preventing thermal stress on critical components.

To improve performance, operators should:

- Regularly inspect air hoses and fittings for leaks.

- Use filtered water to prevent mineral buildup in power water washer attachments.

- Follow manufacturer guidelines for cooling system maintenance in water cooled pressure washer units.

Proper care ensures these machines remain cost-effective over years of heavy use.

Why More Industries Are Making the Switch

The shift from traditional power water washers to air power washers reflects a broader trend toward smarter, safer industrial cleaning. Key reasons for the transition include:

- Reduced Water Usage: Air-assisted cleaning requires less water than standard high-pressure systems.

- Enhanced Safety: Lower risk of injury from uncontrolled pressure spikes.

- Versatility: Adjustable settings accommodate everything from precision parts cleaning to large-scale surface blasting.

When paired with water cooled pressure washer reliability features, these benefits make air power washers a future-proof investment for facilities aiming to improve efficiency while cutting operational risks.

For industrial operations seeking a balance between power and safety, air power washers represent a significant upgrade over conventional power water washers. Their ability to deliver controlled, high-efficiency cleaning—combined with innovations like water cooled pressure washer systems—makes them indispensable in modern manufacturing, transportation, and construction environments.

English

English Español

Español русский

русский