How to Adjust and Control a Variable Displacement Piston Pump Properly?

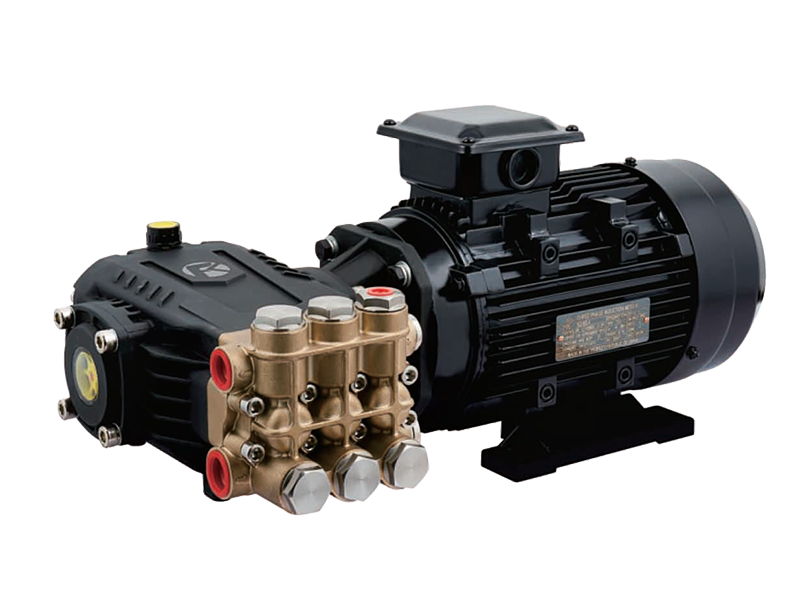

A variable displacement piston pump is a type of pump where the volume of fluid displaced per cycle can be adjusted. This is in contrast to fixed displacement pumps, which move a constant amount of fluid with each cycle. The ability to adjust displacement allows for more efficient energy use and a more tailored flow to meet specific demands, making these pumps ideal for systems where variable flow rates are required.

There are two primary types of piston pumps used in these applications: the axial plunger pump and the radial plunger pump. The axial plunger pump uses pistons arranged parallel to the shaft, offering high pressure and efficiency, making it ideal for applications where high-flow rates and high pressure are essential. The radial plunger pump, on the other hand, uses pistons arranged perpendicular to the shaft, providing outstanding performance in certain hydraulic applications where space constraints are a concern.

Proper Adjustment of a Variable Displacement Piston Pump

Adjusting a variable displacement piston pump involves setting the pump's displacement to match the desired flow rate and pressure. This is typically achieved by manipulating the pump's swash plate or cam ring, which controls the angle at which the pistons operate. Here are a few critical steps for proper adjustment:

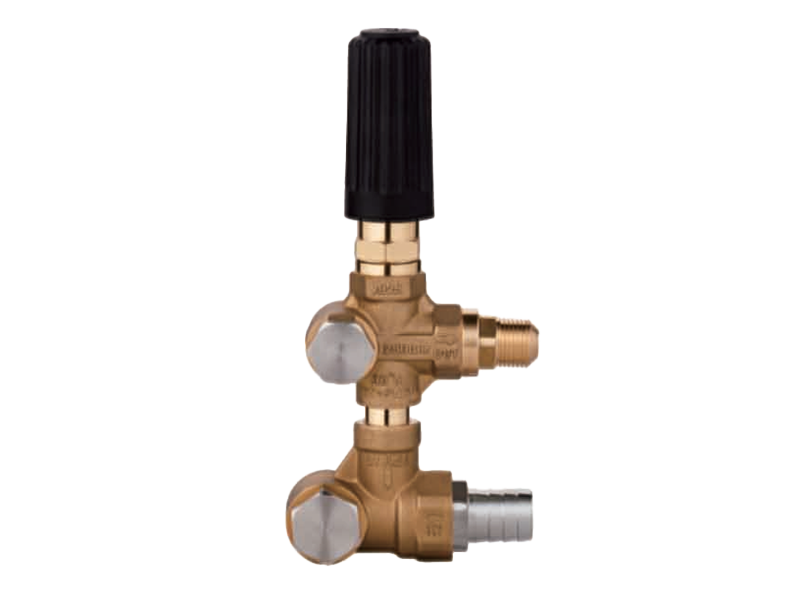

1. Set the Pressure Relief Valve: Before adjusting the displacement, ensure that the pressure relief valve is set to an appropriate pressure level. This will prevent the pump from being over-pressurized, which could cause failure or reduced efficiency. The relief valve helps maintain a consistent pressure, making it easier to control the system.

2. Adjust the Swash Plate Angle: The axial plunger pump typically uses a swash plate to adjust displacement. By changing the angle of the swash plate, you can control the stroke of the pistons, which in turn controls the flow rate. To decrease the flow, reduce the angle of the swash plate; to increase flow, increase the angle. This adjustment should be done gradually to avoid system shocks and to ensure smooth operation.

3. Monitor the Load Demand: In applications where the load is variable, adjusting the pump's displacement based on the demand is crucial. For instance, when a machine requires more power, the radial plunger pump may increase displacement to deliver more fluid to the system. On the other hand, when the load decreases, the displacement can be reduced, saving energy and improving efficiency.

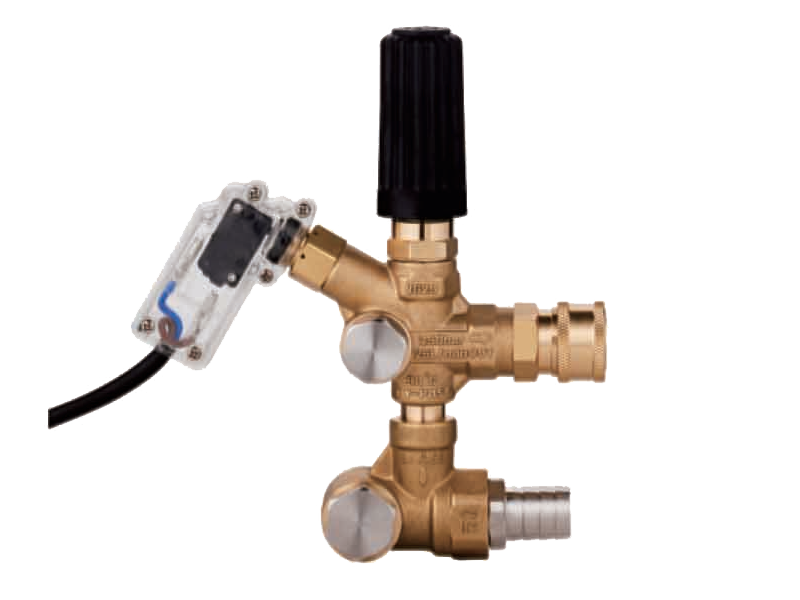

4. Fine-Tuning with Electronic Controls: Modern variable displacement piston pumps often come with electronic control systems that allow for more precise adjustments. These systems use sensors and feedback mechanisms to automatically adjust displacement in response to load changes. Fine-tuning these systems requires understanding the control algorithms and ensuring that the system is calibrated correctly.

5. Check for Leakage and Wear: Over time, seals and components in the pump, such as the pistons and swash plate, may experience wear and tear, cause internal leakage or reduced efficiency. Regular inspection and maintenance are essential to identify and correct these issues. Proper lubrication can help reduce friction and wear on the moving parts, ensuring smoother operation and longer pump life.

Maintenance and Troubleshooting Tips

1.Even with adjustments, pumps can encounter issues due to wear, dirt, or improper settings. Regular maintenance can prevent most failures. Here are some tips for keeping your pump in good condition:

2.Regular Inspection: Periodically check for signs of wear in critical components such as the pistons, swash plate, and seals. Look for any abnormal noises or vibrations, which could indicate internal damage.

3.Keep the Pump Clean: Contaminants such as dirt, debris, or improper fluid can damage the internal components of the pump. Always use the recommended fluids and ensure that the pump is operating in a clean environment.

4.Monitor System Pressure: Keep an eye on the system pressure during operation. Any drastic changes in pressure could indicate a problem with the pump's displacement control, such as a malfunctioning swash plate or an issue with the pressure relief valve.

Regular maintenance and the use of modern electronic controls can further enhance efficiency, making these pumps indispensable in applications where variable flow rates and pressures are crucial.

English

English Español

Español русский

русский