The Benefits of High Pressure Piston Pumps in Energy and Resource Conservation

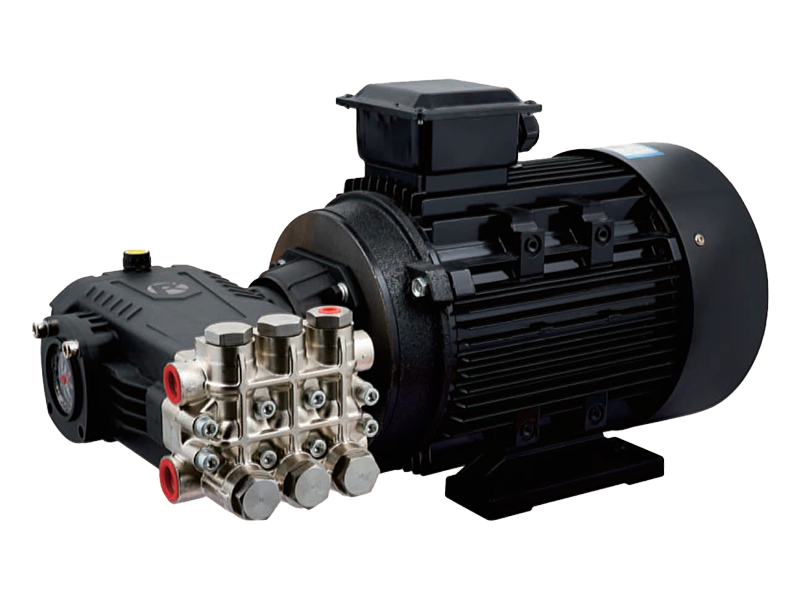

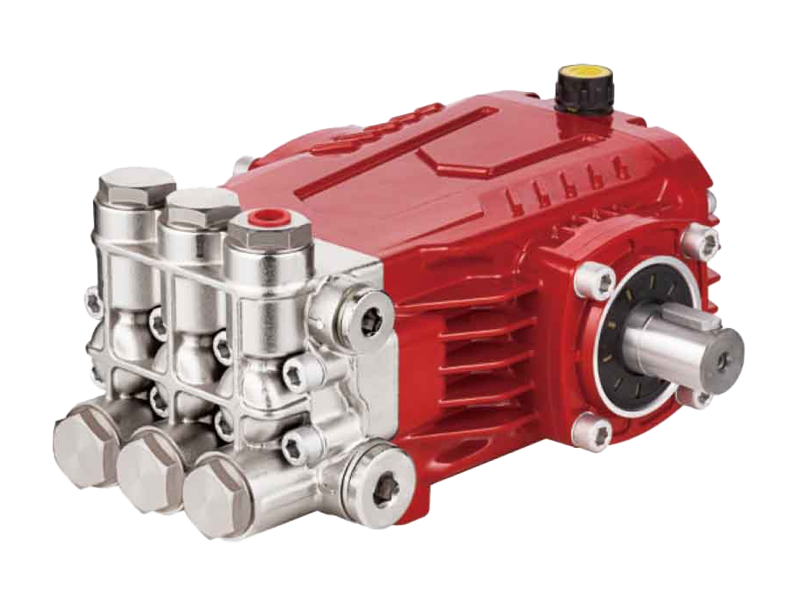

The benefit of high pressure piston pumps, particularly the triplex piston pump, is their unmatched efficiency. These pumps are designed to operate at high pressures, which allows for the transfer of fluids with minimal energy loss. This efficiency translates into significant energy savings, as less power is required to achieve the desired pressure and flow rate. The variable plunger pump, with its adjustable stroke length, further optimizes energy usage by matching the pump's output to the system's exact needs, thereby preventing over-pumping and reducing energy waste.

In addition to their energy-saving capabilities, high pressure piston pumps contribute to resource conservation in various ways. The triplex piston pump, for instance, is renowned for its durability and long service life. This longevity reduces the need for frequent replacements, thereby conserving materials and reducing waste. Similarly, the variable plunger pump's ability to adjust to varying pressure requirements means that it can be used in a wide range of applications without the need for additional pumps, conserving both materials and space.

Another significant benefit of high pressure piston pumps is their role in reducing environmental impact. The high pressure piston pump's efficiency in transferring fluids without loss reduces the carbon footprint associated with energy consumption. Furthermore, the reduced need for maintenance and replacement of these pumps, as exemplified by the triplex piston pump, minimizes the environmental burden caused by manufacturing and disposal processes.

When it comes to applications, high pressure piston pumps, including the variable plunger pump, are versatile and can be found in a variety of industries. In chemical processing, these pumps handle corrosive and abrasive fluids without compromising performance. In oil and gas extraction, triplex piston pumps are relied upon for their ability to deliver high pressure fluids over long distances. The variable plunger pump, with its precision control, is essential in applications requiring precise metering of fluids, such as in pharmaceutical manufacturing.

Maintenance is another area where high pressure piston pumps excel. The simplicity and robustness of these pumps, especially the triplex piston pump, mean that they require less frequent maintenance, which conserves both resources and time. The variable plunger pump also offers ease of maintenance due to its modular design, which allows for quick component replacement without the need for specialized tools.

In terms of cost savings, high pressure piston pumps provide a compelling case. The initial investment in these pumps may be higher than that of traditional pumps, but the long-term savings in energy and maintenance costs make them a wise investment. The variable plunger pump, for example, can save on operational costs by precisely matching the pump output to the system demand, thus avoiding energy waste.

The reliability of high pressure piston pumps is a key factor in their appeal. The triplex piston pump, in particular, is known for its ability to maintain consistent performance even under demanding conditions. This reliability is crucial for industries where downtime can cause significant losses. The variable plunger pump also stands out for its dependability, ensuring a steady flow of fluids even when operating under fluctuating pressure conditions.

In conclusion, high pressure piston pumps, including the triplex piston pump and variable plunger pump, are indispensable in the pursuit of energy efficiency and resource conservation. Their ability to reduce energy consumption, minimize waste, and maintain performance under challenging conditions makes them an invaluable asset in today's resource-conscious world. As industries continue to seek sustainable solutions, the role of high pressure piston pumps in this endeavor is only set to grow.

English

English Español

Español русский

русский