Inlet and Outlet Materials for Three Plunger High Pressure Pumps

Three Plunger High Pressure Pumps are widely used in industrial applications such as water treatment, chemical processing, oil and gas, and power generation. The choice of materials for the pump’s inlet and outlet components is critical for durability, reliability, and resistance to corrosion. Selecting the right materials ensures suitable performance, reduces maintenance costs, and prolongs the lifespan of the pump. Understanding the factors that influence material selection and corrosion resistance helps engineers and operators make informed decisions.

Importance of Material Selection

The inlet and outlet components of a Three Plunger High Pressure Pump are constantly exposed to fluids under high pressure, which can include water, chemicals, or abrasive liquids. Materials must be able to withstand pressure, resist corrosion, and prevent contamination of the pumped fluids. Inadequate material selection can cause premature wear, leaks, and system downtime. Choosing the right material improves efficiency, reduces maintenance, and ensures consistent performance even in demanding industrial environments.

Common Material Options

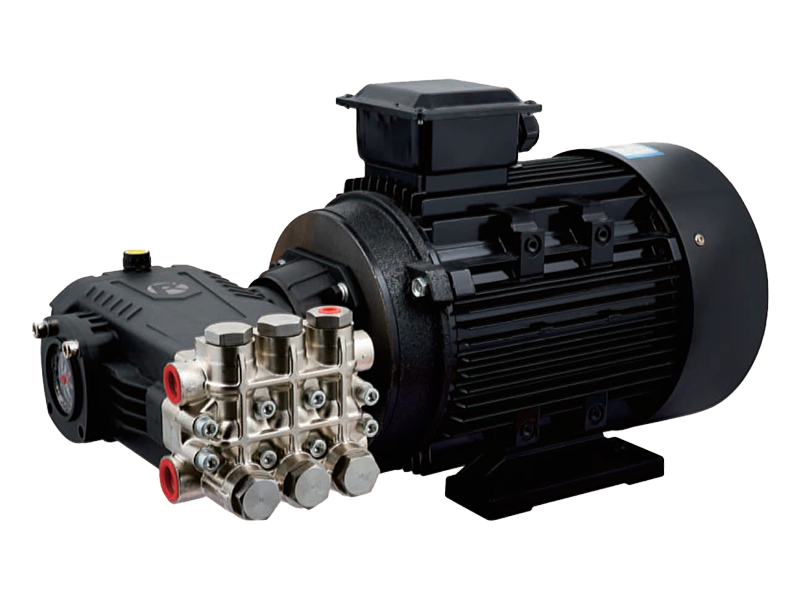

Several materials are commonly used for the inlet and outlet parts of Three Plunger High Pressure Pumps. Stainless steel is a popular choice due to its good corrosion resistance and durability in both fresh and saline water applications. Bronze is often used for its good resistance to wear and moderate corrosion protection, especially in less aggressive environments. For chemical applications, high-grade alloys such as Hastelloy or Duplex stainless steel may be required to withstand highly corrosive fluids. Each material offers a balance of corrosion resistance, mechanical strength, and cost, which must be considered according to the intended application.

Evaluating Corrosion Resistance

Corrosion resistance is influenced by factors such as fluid composition, temperature, pH levels, and the presence of abrasive particles. Stainless steel alloys, for example, resist oxidation and chemical attack in neutral to mildly acidic fluids. Duplex stainless steel or nickel-based alloys provide good resistance in highly corrosive or acidic environments. Evaluating these factors ensures that the inlet and outlet components maintain integrity, reduce leakage risk, and reduce the need for frequent replacement. Material testing and manufacturer specifications provide valuable guidance in this evaluation.

Maintenance and Longevity Considerations

Proper material selection contributes to reduced maintenance requirements and extended service life. Corrosion-resistant materials reduce the formation of rust, scaling, or pitting, which can compromise pump efficiency. Regular inspection and cleaning further enhance longevity, especially in environments with high mineral content or chemical exposure. Choosing durable materials also prevents unexpected downtime and keeps operational costs under control, which is particularly important for high-demand industrial systems.

Application-Specific Recommendations

The choice of inlet and outlet materials should be tailored to specific industrial applications. For water treatment, stainless steel is typically sufficient, while chemical processing may require more specialized alloys. Saltwater or marine applications demand corrosion-resistant metals capable of withstanding both oxidation and chloride-induced corrosion. Consulting with pump manufacturers and reviewing material specifications ensures that the selected components meet operational requirements, maintain reliability, and provide cost-effective performance.

Selecting appropriate inlet and outlet materials for a Three Plunger High Pressure Pump is crucial for performance, corrosion resistance, and longevity. Considering factors such as fluid type, temperature, pH, and industrial application allows operators to choose materials that balance durability, efficiency, and cost. Stainless steel, bronze, and specialized alloys provide various levels of corrosion protection to suit different conditions. Proper material selection, combined with routine maintenance, ensures that the pump operates reliably, reduces downtime, and delivers consistent results in demanding environments.

English

English Español

Español русский

русский