What Are the Common Repairs Needed for Heavy-Duty Pressure Washers?

Heavy duty commercial pressure washers are engineered to deliver high water pressure for cleaning applications that demand durability and reliability. Similarly, heavy duty electric power washers offer the same level of performance but are powered by electricity, making them suitable for indoor and outdoor use where a power source is readily available. Heavy duty high pressure washers are often chosen for their ability to handle large-scale cleaning tasks with precision and efficiency.

Common Repairs for Heavy-Duty Pressure Washers

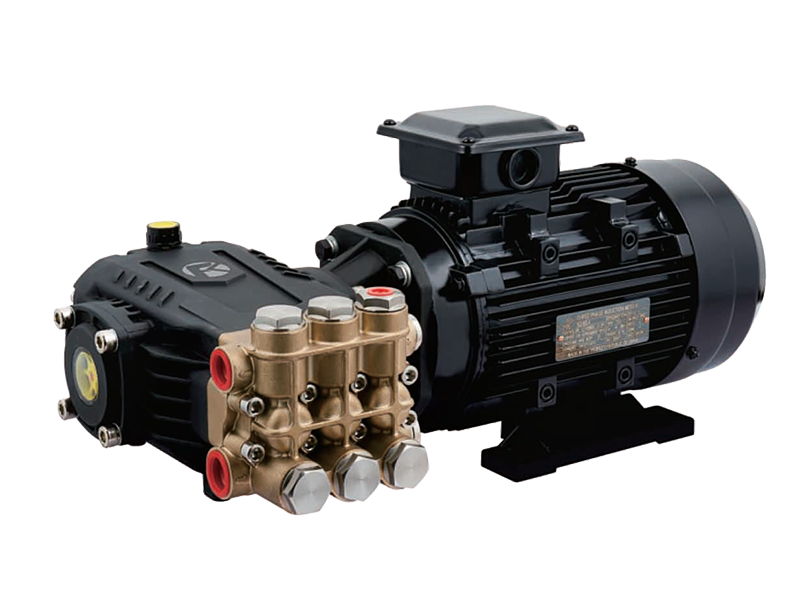

1. Pump Maintenance and Repairs

The pump is the heart of any heavy duty commercial pressure washer. Over time, the pump may require repairs due to wear and tear or blockages from debris. Regularly inspecting and cleaning the pump can prevent more extensive damage. In some cases, a pump rebuild or replacement may be necessary for heavy duty electric power washers and heavy duty high pressure washers that have been subjected to heavy use.

2. Hose and Nozzle Replacement

The high-pressure hoses and nozzles of heavy duty pressure washers are subject to wear from the pressure and the elements. Checking for cracks or leaks in the hose is essential, as is ensuring that nozzles are free from clogs. Replacement parts can extend the life of a heavy duty commercial pressure washer and maintain good cleaning performance.

3. Trigger Gun and Lance Repairs

The trigger gun and lance are the direct interfaces through which users control the heavy duty electric power washer. Overuse can cause wear and tear, affecting the performance of the heavy duty high pressure washer. Regular maintenance includes lubricating the trigger mechanism and checking for any leaks or damage that may require repair or replacement.

4. Electrical System Checks

For heavy duty electric power washers, the electrical system is a critical component. Regular checks should be performed on the power cord, plug, and any internal wiring for signs of fraying or damage. Ensuring the electrical components are in good condition is vital for the safe operation of heavy duty commercial pressure washers.

5. Engine Service for Gas-Powered Models

Gas-powered heavy duty high pressure washers require regular engine maintenance. This includes checking and changing oil, replacing spark plugs, and ensuring the air filter is clean. These services help maintain the engine's performance and prolong the life of the heavy duty pressure washer.

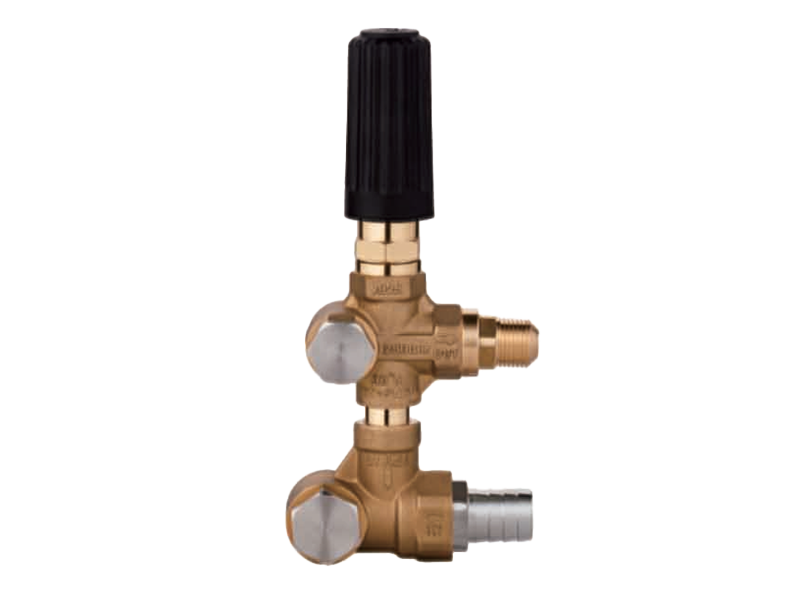

6. Thermal Relief Valve Inspection

The thermal relief valve is a safety feature found in many heavy duty commercial pressure washers. It prevents the pump from overheating by releasing pressure when the temperature reaches a certain threshold. Regularly inspecting this valve for proper operation can prevent damage to the pump in heavy duty electric power washers and heavy duty high pressure washers.

7. Pump Seals and Bearings

Wear and tear on pump seals and bearings are common issues for heavy duty pressure washers. Checking these components for signs of wear and replacing them as needed can prevent leaks and maintain the efficiency of heavy duty commercial pressure washers.

8. Unblock the Strainer

The strainer in heavy duty electric power washers and heavy duty high pressure washers is designed to keep debris from entering the pump. Over time, it can become clogged with dirt and small particles. Regularly cleaning the strainer ensures that water flows freely, maintaining the performance of heavy duty pressure washers.

9. Check and Replace the Pressure Switch

The pressure switch is responsible for turning the heavy duty commercial pressure washer on and off based on the water pressure. If it becomes faulty, it can cause the machine running continuously or not starting at all. Regularly testing and replacing the pressure switch as necessary can prevent these issues.

10. Regular Inspection of the Frame and Mounting

Heavy duty high pressure washers and heavy duty electric power washers are often mounted on carts or stands for mobility. Over time, the frame and mounting points can become damaged or weakened. Regularly inspecting these parts for signs of wear and making necessary repairs or replacements can ensure the stability and safety of the pressure washer.

In conclusion, heavy-duty pressure washers are indispensable tools in many industries, and their upkeep is crucial for their longevity and efficiency.

English

English Español

Español русский

русский