What Makes Industrial Triplex Pumps great for High-Pressure Water Systems in Manufacturing?

In industrial manufacturing, high-pressure water systems are essential for a wide range of applications, including cleaning, cooling, and processing. One of reliable and efficient types of pumps used in these systems is the industrial triplex pump. These pumps, known for their ability to handle extremely high-pressure applications, are great for providing the necessary water flow and pressure required for demanding manufacturing processes.

Consistent High-Pressure Performance

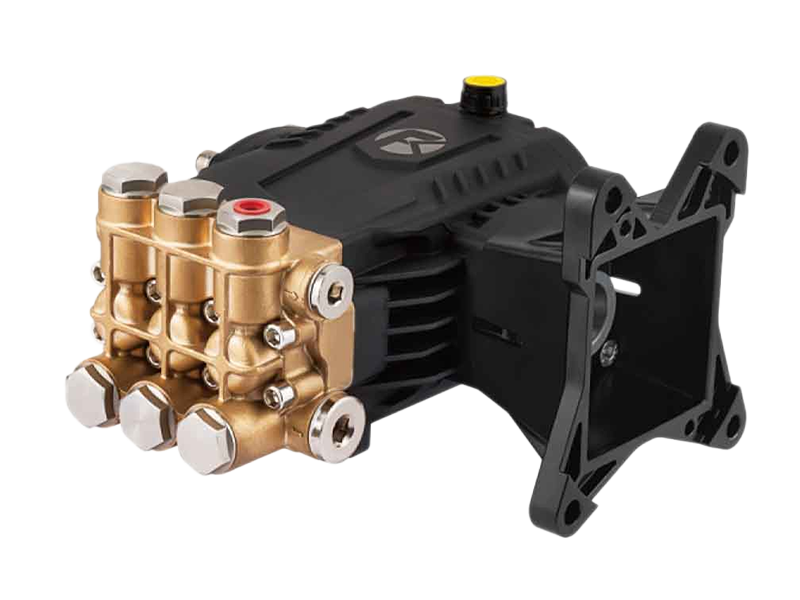

One of the key reasons why industrial triplex pumps are so popular in high-pressure water systems is their ability to deliver consistent, high-pressure water flow. These pumps are designed with three pistons, which work in unison to provide a smooth and reliable output. Unlike single or duplex pumps, the triplex industrial pump can generate higher pressure with better flow stability. This makes them an outstanding choice for heavy-duty applications such as metal cutting, equipment cleaning, or industrial washing tasks.

The triplex booster pump, for example, is commonly used to increase the pressure within a water system, ensuring that water reaches the desired pressure levels for particular applications. The combination of multiple pistons in these pumps reduces the risk of pressure fluctuations, allowing for more precise control over the water flow. Whether it's for industrial cleaning, cooling, or any other high-pressure operation, the consistent performance of the industrial triplex pump ensures reliable operation and efficient results.

Durability and Long-Term Reliability

Manufacturing environments can be harsh, with exposure to debris, chemicals, and other potentially damaging materials. Industrial triplex pumps are designed with durability in mind, often made from heavy-duty materials such as stainless steel or forged steel, making them capable of withstanding the tough conditions of industrial settings. They are less prone to wear and tear compared to other pumps, which ensures long-term reliability even in high-demand applications.

The triplex power washer, used for industrial cleaning purposes, also benefits from the durability of triplex pump technology. These pumps are built to handle the high pressures associated with industrial power washing, whether it's cleaning large machines, factory floors, or processing equipment. With regular maintenance, industrial triplex pumps can operate for years without significant performance degradation, making them a cost-effective option in the long run.

Versatility Across Industries

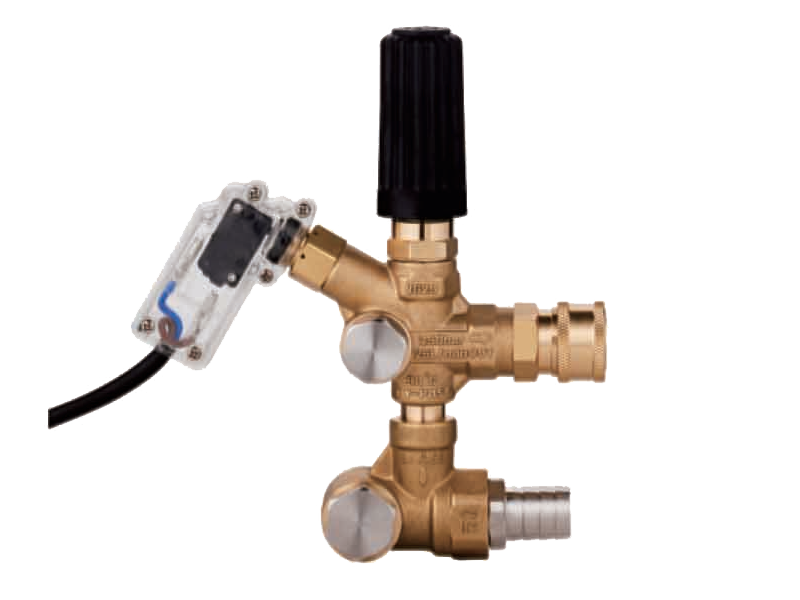

Industrial triplex pumps are incredibly versatile and can be used across a wide range of industries. In manufacturing, these pumps can be found in applications such as cleaning, cooling, and even in the injection of chemicals or other fluids into systems. The ability to handle both low and high-flow applications makes these pumps suitable for different manufacturing needs. For instance, the triplex booster pump can be used to increase water pressure in a system for specific tasks, while the triplex power washer is great for cleaning equipment and surfaces in factories, warehouses, or industrial kitchens.

Moreover, the precise pressure control offered by these pumps makes them invaluable in delicate operations, such as cooling systems or chemical applications, where an even and steady flow is necessary. In contrast, other pumps might struggle to offer the same level of precision, especially in more sensitive manufacturing processes.

Efficiency and Energy Savings

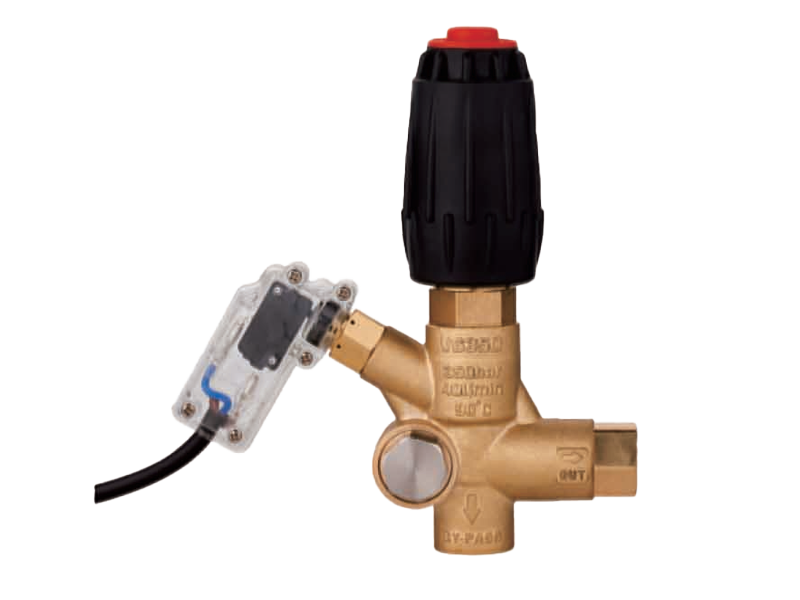

One of the key factors to consider when choosing a pump for industrial use is energy efficiency. Industrial triplex pumps are engineered to improve performance while minimizing energy consumption. By delivering high pressure with relatively low energy input, these pumps help reduce operational costs, making them an outstanding choice for companies that are conscious of their energy consumption.

In comparison to other pumps, the triplex booster pump is particularly effective at optimizing energy usage in pressure systems. It boosts pressure without significantly increasing the energy needed to maintain that pressure, allowing for more efficient system operation. This can translate into long-term cost savings for businesses, as they do not need to constantly invest in energy-intensive equipment.

Low Maintenance and Easy Serviceability

While high-pressure pumps are expected to perform under demanding conditions, the maintenance requirements for an industrial triplex pump are relatively low compared to other types of pumps. These pumps are designed with fewer moving parts and are easy to service, reducing the need for frequent repairs or part replacements. Additionally, their efficient design means they are less likely to experience issues such as overheating or clogging.

The triplex power washer, which utilizes the industrial triplex pump, also benefits from these low-maintenance characteristics. Power washers used in industrial cleaning operations often need to operate for long hours, and downtime for repairs can be costly. The durability and reliability of industrial triplex pumps help keep these systems running smoothly with minimal disruption.

English

English Español

Español русский

русский