Choosing a Stainless Steel Pump for Chemical and Marine Applications?

In demanding industrial environments where corrosion and chemical resistance are paramount, stainless steel pumps have become the equipment of choice. Unlike standard pumps that quickly deteriorate when exposed to harsh conditions, these robust machines maintain their integrity while handling everything from seawater to aggressive chemicals. This makes them particularly valuable for operations that also utilize high-pressure cleaning systems like High Pressure Washer units or industrial Electric Pressure Washer equipment.

The outstandingity of stainless steel pumps becomes especially apparent in marine settings. Constant exposure to saltwater rapidly destroys conventional pumps, but stainless steel construction resists corrosion while maintaining peak performance. This durability is equally crucial for chemical plants where pumps must withstand acidic or caustic solutions that would eat through lesser materials. When these pumps are integrated with High Pressure Washer systems for equipment cleaning or surface preparation, their corrosion resistance ensures reliable operation even when handling contaminated wash water.

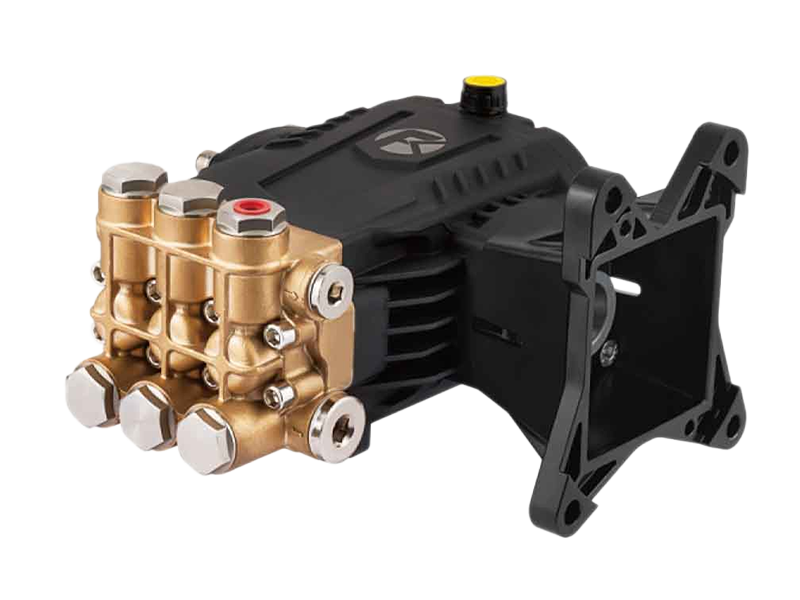

Several key factors make stainless steel pumps ideal for pairing with Electric Pressure Washer systems in challenging environments. Their non-reactive nature prevents contamination of sensitive processes, while their structural strength handles the vibration and pressure fluctuations common in industrial cleaning applications. Many modern stainless steel pump designs now incorporate features specifically for compatibility with High Pressure Washer technology, including reinforced seals and specialized impeller designs that optimize fluid dynamics.

The advantages extend beyond mere corrosion resistance. Stainless steel pumps used with Electric Pressure Washer systems demonstrate outstanding longevity, often lasting several times longer than their conventional counterparts in identical operating conditions. This extended service life offsets their higher initial cost, particularly when used in continuous operations where downtime for pump replacement carries significant expense. Their smooth interior surfaces also resist scaling and buildup, maintaining efficiency over time.

For facilities that rely on High Pressure Washer equipment for regular maintenance, the choice of pump material becomes critical. Stainless steel models prevent the iron contamination that can occur with standard pumps, while their robust construction handles the pulsating loads characteristic of Electric Pressure Washer operation. Many industrial operators report dramatically reduced maintenance requirements after switching to stainless steel pump systems.

The integration of stainless steel pumps with High Pressure Washer and Electric Pressure Washer systems continues to evolve. New designs focus on improving energy efficiency while maintaining the material's inherent durability. Some manufacturers are developing smart stainless steel pumps that can communicate with Electric Pressure Washer controls to optimize performance based on real-time operating conditions.

Selecting a stainless steel pump for chemical or marine applications - especially those involving High Pressure Washer systems - represents a sound long-term investment. The combination of corrosion resistance, mechanical strength, and compatibility with harsh operating environments makes these pumps indispensable for industries where equipment reliability cannot be compromised. As Electric Pressure Washer technology advances to handle more challenging cleaning tasks, stainless steel pumps will continue to provide the dependable performance that industrial operators require.

This dual focus on environmental responsibility and operational reliability positions stainless steel pumps as future-proof solutions for industries facing tightening regulations and demanding operating conditions alike. Their ability to withstand punishing environments while integrating seamlessly with advanced High Pressure Washer and Electric Pressure Washer technologies ensures they will remain the backbone of critical industrial processes for years to come.

English

English Español

Español русский

русский