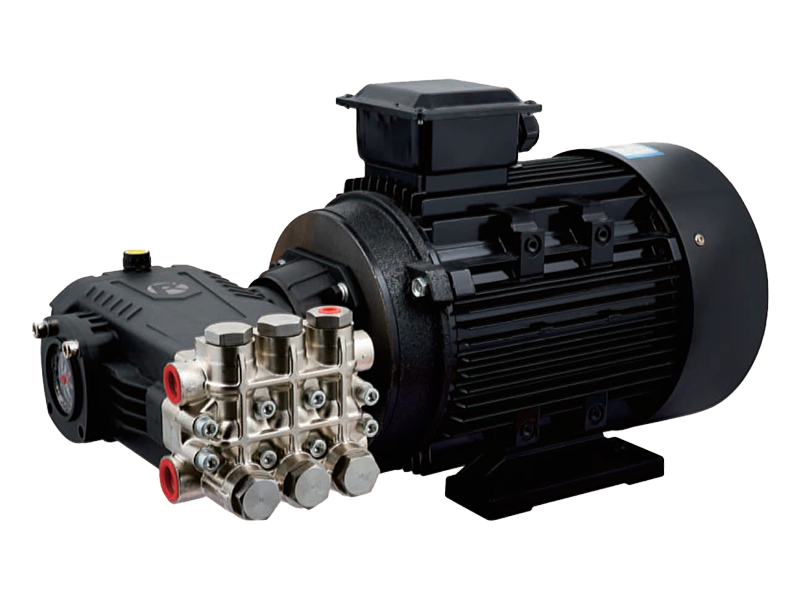

Power Consumption of a High Pressure Pump and Its Impact on Operational Efficiency

What Influences Power Consumption in a High Pressure Pump?

The power consumption of a High Pressure Pump depends on several key factors, including the operating pressure, flow rate, pump design, and the type of fluid being pumped. Generally, as the pressure and flow requirements increase, the energy needed to drive the pump also rises. They are designed to deliver water or other fluids at elevated pressures, which inherently requires more power compared to low-pressure systems.

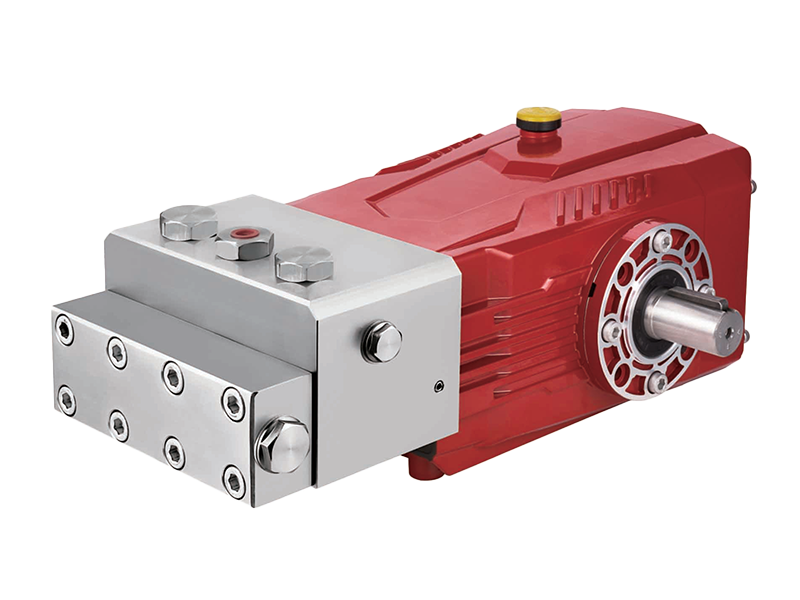

Efficiency of the Pump Design

The efficiency of a High Pressure Pump plays a crucial role in determining its power consumption. Pumps with optimized hydraulic design, high-quality materials, and precision manufacturing tend to convert electrical or mechanical input energy into fluid flow more effectively. Higher efficiency means less wasted energy, which translates into lower power consumption for the same output. Conversely, pumps with poor design or worn components may consume excessive power due to losses caused by friction, leakage, or turbulence inside the pump.

Operating Conditions and Their Effect on Power Use

Operating a High Pressure Pump within its recommended parameters helps maintain suitable power consumption. Running the pump at pressures or flow rates beyond its design limits can cause excessive energy use and potential damage. Additionally, variations in fluid viscosity or temperature may affect the pump’s load, influencing power demands. For example, pumping thicker or hotter fluids can increase resistance and power requirements.

Power Consumption Compared to Other Pump Types

High Pressure Pumps naturally consume more power than low or medium-pressure pumps due to the higher forces involved in generating pressure. However, when compared to other high-pressure fluid-moving equipment, their energy use can be competitive, especially when selecting models engineered for energy efficiency. Variable speed drives and advanced control systems can further reduce power consumption by adjusting pump operation to actual demand rather than running at full capacity continuously.

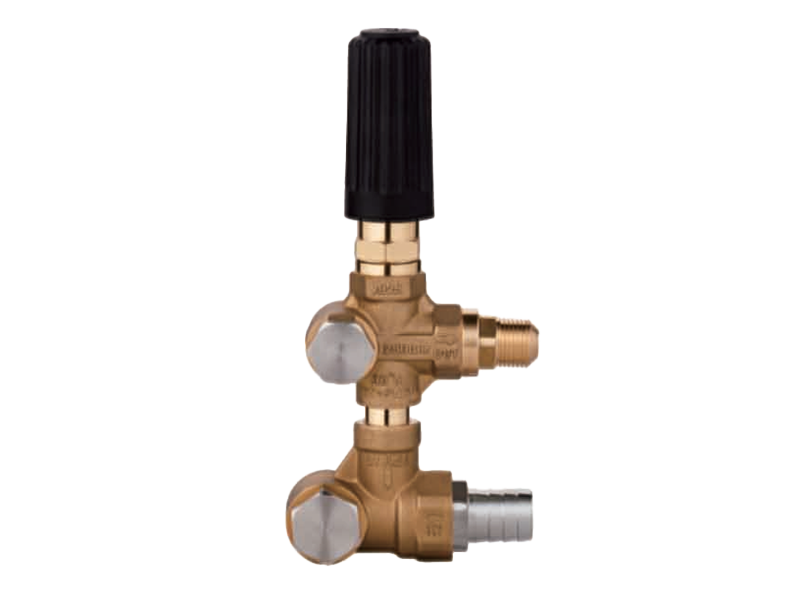

Energy Saving Strategies for High Pressure Pumps

To reduce power consumption, several strategies can be employed. Using pumps with high-efficiency motors reduces electrical energy use. Implementing variable frequency drives (VFDs) allows the pump to operate at speeds matching the required flow and pressure, avoiding unnecessary power use. Routine maintenance, such as lubrication, cleaning, and replacing worn parts, helps maintain pump efficiency and prevents energy waste. Additionally, selecting the right pump size and model for the application ensures operation within suitable efficiency ranges.

Economic and Environmental Considerations

Power consumption is a significant factor in the operating costs of High Pressure Pumps, especially in industrial or commercial applications where pumps run for extended periods. Lower energy use not only reduces electricity bills but also decreases the environmental footprint by cutting greenhouse gas emissions associated with power generation. Therefore, investing in energy-efficient pumps and operational practices offers both financial and sustainability benefits.

Conclusion: Power Consumption of High Pressure Pumps Can Be Managed Effectively

While high-pressure pumps generally consume more power than lower-pressure counterparts due to their function, their power use can be optimized through careful pump selection, proper operation, and regular maintenance. Advances in pump technology and control systems continue to improve energy efficiency, making modern high-pressure pumps more economical and environmentally friendly. Understanding these factors helps users balance performance needs with power consumption for suitable operational efficiency.

English

English Español

Español русский

русский