Exploring Whether High Pressure Pumps Are Equipped with Overload Protection Features

Understanding Overload Protection in High Pressure Pumps

Overload protection is a crucial safety feature designed to prevent damage to High Pressure Pumps when operating conditions exceed safe limits. This protection mechanism helps avoid mechanical failures caused by excessive current, pressure, or temperature, which can cause costly repairs and downtime. Understanding whether a high-pressure pump is equipped with such protection is vital for industries relying on continuous and safe operation.

Types of Overload Protection Mechanisms

High Pressure Pumps may incorporate various types of overload protection depending on their design and application. Common methods include thermal overload relays that monitor motor temperature, current sensors that detect excessive electrical load, and pressure relief valves that prevent pressure spikes. These components work together to detect abnormal operating conditions and trigger protective actions such as shutting down the pump or reducing its load.

Thermal Overload Protection

Thermal overload protection involves sensors embedded in the pump motor that detect overheating. When the temperature exceeds a preset threshold, the system automatically stops the pump to prevent damage to windings and other components. This feature is particularly important in continuous operation scenarios where overheating risks are higher due to extended use.

Electrical Current Overload Protection

Current overload protection monitors the electrical current drawn by the pump motor. If the current surpasses safe levels, often caused by mechanical blockage or excessive load, the system interrupts the power supply to the pump. This prevents motor burnout and mechanical damage, ensuring safer operation and longer pump life.

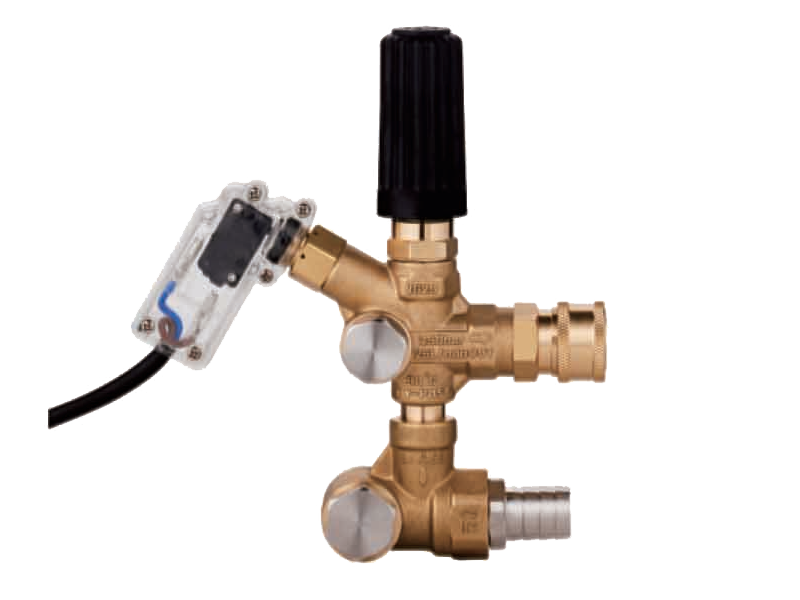

Pressure-Based Overload Protection

Pressure overload protection uses relief valves or sensors to monitor the pressure within the pumping system. If the pressure rises beyond the pump’s rated capacity, the relief valve opens or the control system initiates a shutdown to avoid damage to seals, impellers, and piping. This feature is essential in applications where pressure fluctuations are common.

Integration with Control Systems

Modern High Pressure Pumps often integrate overload protection with advanced control systems. Programmable logic controllers (PLCs) or variable frequency drives (VFDs) can monitor multiple parameters simultaneously and respond dynamically to overload conditions. These systems provide alarms, automatic shutdown, and diagnostic information, enhancing operational safety and maintenance planning.

Benefits of Overload Protection in High Pressure Pumps

Equipping High Pressure Pumps with overload protection reduces the risk of catastrophic failures and extends equipment lifespan. It reduces unplanned downtime and maintenance costs, improves workplace safety, and ensures compliance with industrial safety standards. Moreover, early detection of overload conditions enables timely interventions before severe damage occurs.

Considerations When Selecting Pumps with Overload Protection

Not all High Pressure Pumps come standard with overload protection; it may be offered as an optional feature or incorporated into the control system. When selecting a pump, users should assess their application’s risk factors, operating environment, and safety requirements. Choosing pumps with built-in or compatible overload protection devices enhances reliability and protects investment.

Maintenance and Testing of Overload Protection Systems

To ensure continued effectiveness, overload protection components require regular maintenance and testing. Periodic inspection of sensors, relays, and valves helps detect faults or calibration drift. Functional tests simulate overload conditions to verify that protection mechanisms activate correctly, maintaining system readiness and safety.

Conclusion: Overload Protection Significantly Enhances High Pressure Pump Safety and Reliability

High Pressure Pumps can be equipped with various overload protection features designed to safeguard against electrical, thermal, and pressure-related failures. These systems are integral to maintaining pump performance, reducing damage risks, and extending operational life. Understanding and implementing appropriate overload protection is essential for industries seeking safe and efficient pump operation in demanding applications.

English

English Español

Español русский

русский