Evaluating the Durability of High Pressure Pumps During Extended Continuous Operation in Industrial Settings

Durability Challenges Faced by High-Pressure Pumps in Continuous Use

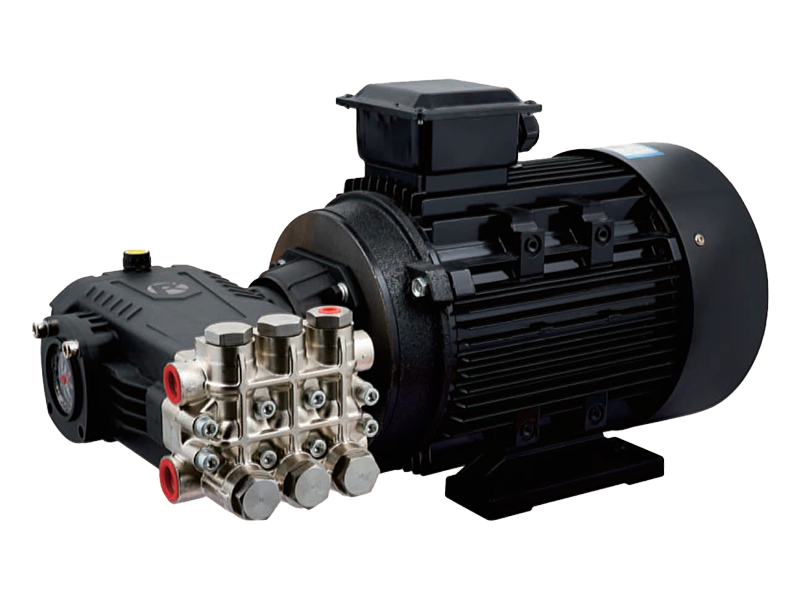

High Pressure Pumps are critical components in many industrial processes where continuous operation is often required. However, operating nonstop can expose these pumps to significant mechanical stress, thermal strain, and wear. Understanding how durable a High Pressure Pump is under prolonged running conditions helps ensure reliability, reduce downtime, and lower maintenance costs.

Material Quality and Structural Design

The durability of a High Pressure Pump during continuous use largely depends on the materials and design employed. Pumps made from high-grade stainless steel, hardened alloys, or corrosion-resistant composites tend to withstand wear, pressure, and corrosion better than those made from inferior materials. Additionally, robust structural design with reinforced housings and precision-machined components enhances the pump’s ability to resist fatigue and deformation over long periods.

Thermal Management and Lubrication Importance

Continuous operation generates heat that can degrade internal components and lubricants if not properly managed. Effective cooling systems, such as water jackets or air fans, and high-quality lubricants are essential to maintain suitable operating temperatures. Proper thermal management helps prevent overheating, reduces friction-related wear, and extends the service life of bearings, seals, and other critical parts.

Seal and Bearing Longevity

Seals and bearings are among the vulnerable parts in a continuously running High Pressure Pump. Seals must maintain a tight barrier to prevent leaks while enduring pressure fluctuations and chemical exposure. Bearings support rotating components and absorb mechanical loads. Using durable seal materials and high-precision bearings, combined with regular maintenance, greatly contributes to the pump’s durability during extended operation.

Impact of Operating Conditions on Durability

Environmental and operational factors such as fluid type, pressure, temperature, and contamination levels directly influence pump lifespan. Abrasive or corrosive fluids accelerate wear, while fluctuating pressure and temperature cause stress on components. Maintaining stable and suitable operating conditions is vital to preserving the pump’s durability during continuous use.

Maintenance Practices to Enhance Continuous Operation

Routine inspection, cleaning, lubrication, and timely replacement of worn parts are critical to sustaining pump durability. Condition monitoring through vibration analysis, temperature checks, and performance tracking allows early detection of potential issues. Proactive maintenance decreases the risk of unexpected failures and extends the operational life of High Pressure Pumps under continuous workloads.

Technological Advancements Supporting Durability

Modern High Pressure Pumps often feature improved materials, coatings, and smart monitoring technologies that enhance durability. Innovations like ceramic coatings on internal surfaces reduce friction and corrosion, while integrated sensors provide real-time feedback on pump health. These advancements help pumps perform reliably during long-term continuous operation with reduced maintenance needs.

Industrial Applications Demonstrating Pump Durability

In industries such as chemical processing, water treatment, and oil & gas, High Pressure Pumps are frequently run nonstop to meet production demands. Case studies show that pumps built with durable materials and maintained correctly can operate efficiently for thousands of hours. Conversely, pumps lacking appropriate design or maintenance often suffer premature wear and failures.

Conclusion: High Pressure Pumps Can Achieve High Durability Under Continuous Operation With Proper Design and Care

High-pressure pumps are capable of sustained, reliable performance during continuous operation when constructed with quality materials, equipped with effective thermal management, and supported by rigorous maintenance. Understanding the interplay of design, environment, and upkeep is key to improving pump durability. With these factors in place, industries can confidently rely on High Pressure Pumps for demanding, nonstop applications.

English

English Español

Español русский

русский