Does a Double Plunger Pump Improve Pumping Efficiency in High-Pressure Applications?

Among the various types of pumps used in such settings, the double plunger pump is often considered a preferred solution for improving pumping efficiency. This pump, which features two plungers working in tandem, provides several advantages over single-plunger pumps. But how does a double plunger pump improve pumping efficiency in high-pressure environments, and what makes it stand out when compared to other pump types like the duplex piston pump and electric piston pump?

Understanding the Double Plunger Pump

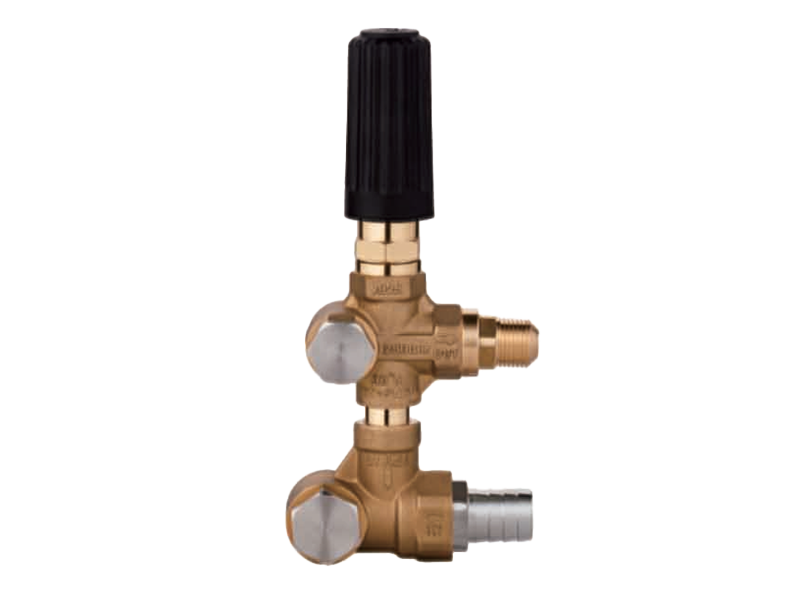

A double plunger pump is designed to handle high-pressure applications, making it ideal for industries that require substantial water or fluid output under high pressure, such as cleaning, mining, and manufacturing. This pump consists of two plungers that work simultaneously, each drawing and expelling fluid in a continuous cycle. The two plungers help balance the workload, reducing the strain on any one plunger, and ensuring a more even and consistent fluid flow.

In contrast to single-plunger pumps, a double plunger pump can generate higher flow rates while maintaining the necessary pressure. This results in better efficiency, especially in environments where consistent and powerful output is needed.

Advantages of the Double Plunger Pump in High-Pressure Applications

1. Increased Efficiency Through Continuous Flow

One of the primary benefits of the double plunger pump is its ability to provide a continuous and more consistent flow of fluid, which is essential for high-pressure applications. In a high-pressure system, where constant and reliable fluid flow is necessary, the double plunger design ensures that one plunger is always at the peak of its cycle while the other is in a recovery phase. This alternation minimizes pulsation, creating a smoother, more consistent pressure output. Such efficiency is crucial in industrial applications where fluctuations in pressure can disrupt operations.

2. Enhanced Durability and Performance

The double plunger pump design also contributes to the durability of the pump. By distributing the workload between two plungers, the pump reduces the chances of wear and tear on any single component, extending the lifespan of the pump. This makes the double plunger pump particularly well-suited for high-pressure environments where long hours of operation are common. The reliability of the pump in these conditions directly contributes to overall system performance and cost-effectiveness.

3. outstanding Pressure and Flow Rate

For applications that require a high pressure over an extended period, such as in water jetting or industrial cleaning, the double plunger pump offers outstanding performance compared to simpler pump designs. The dual-plunger mechanism is capable of maintaining a high pressure without significant fluctuations in output. This makes it an ideal choice for tasks that demand consistent pressure, ensuring good performance for machinery and cleaning equipment.

Comparison with the Duplex Piston Pump

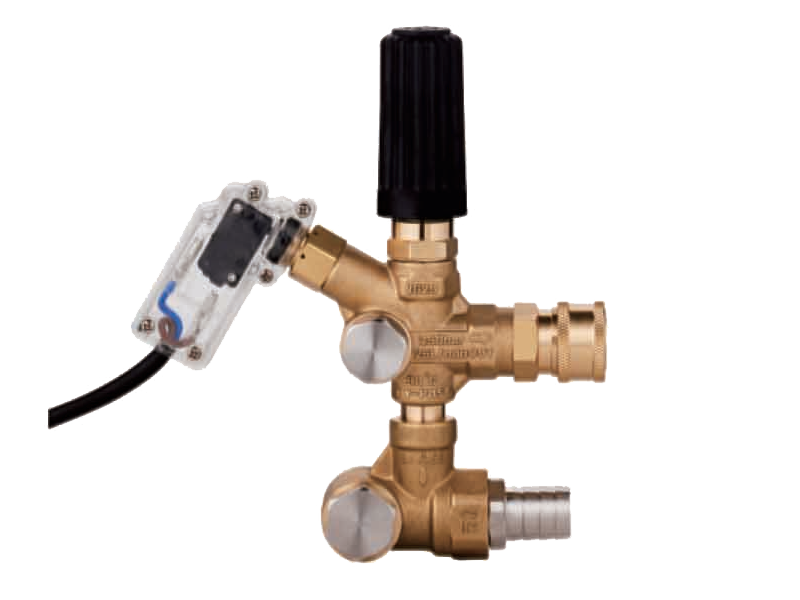

While the double plunger pump offers significant benefits, it's essential to understand how it compares to similar systems like the duplex piston pump. A duplex piston pump is often used in high-pressure applications due to its dual-piston design, which, like the double plunger, provides improved fluid delivery and pressure consistency. However, the double plunger pump typically features simpler mechanics and may be easier to maintain, making it an attractive option for industries seeking reliability without the complexity of a piston-based system.

The duplex piston pump, while highly efficient, may have more moving parts, cause higher maintenance requirements and potentially more downtime. The double plunger pump, on the other hand, offers a more straightforward and durable alternative, often at a lower operating cost, making it ideal for high-pressure operations that require minimal maintenance.

The Role of the Electric Piston Pump

An electric piston pump is often used in applications requiring electric power to drive the pump's motion. These pumps are particularly popular in automated systems, where electric power can drive the piston to generate high pressure. However, while electric piston pumps are effective in specific scenarios, the double plunger pump can sometimes outperform them, especially when it comes to fluid handling in conditions. The double plunger pump is less dependent on external power sources and can deliver consistent high-pressure output without the need for constant electrical power, making it a versatile choice for a wide range of applications.

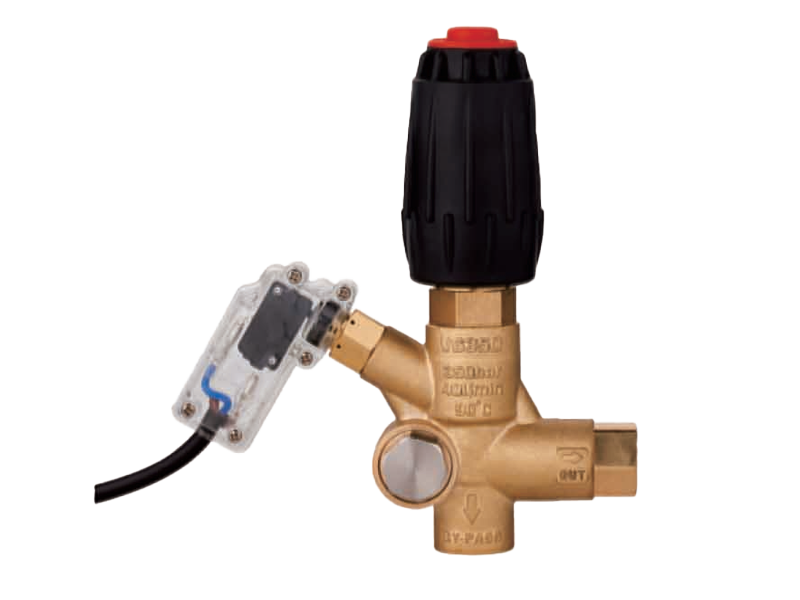

Applications in High-Pressure Industries

The benefits of the double plunger pump make it especially useful in various industries that rely on high-pressure systems. From industrial cleaning systems to pressure testing, these pumps are commonly used in environments where efficiency, durability, and consistent output are non-negotiable. The double plunger pump can easily be integrated into existing systems and is particularly effective in environments like oil and gas extraction, mining, and other heavy-duty applications that require both high flow and high pressure.

English

English Español

Español русский

русский