How to Choose the Right Axial Flow Piston Pump for Precision Applications?

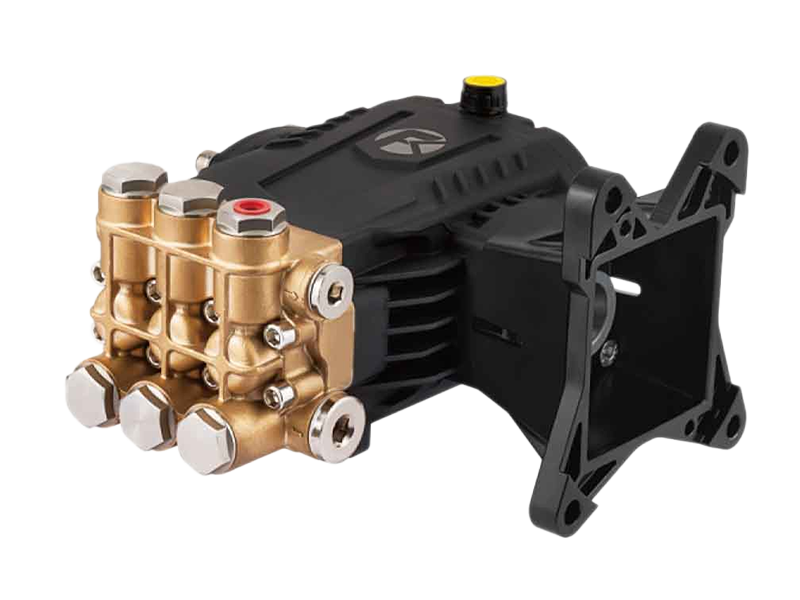

An axial flow piston pump is a type of positive displacement pump that operates by using pistons arranged in a parallel or axial manner. This design enables the pump to deliver a smooth, continuous flow of fluid, which is essential for precision applications where stability and consistency are key. The key benefit of an axial flow piston pump is its ability to operate at high pressures while maintaining a relatively compact size. This makes it ideal for systems where space is limited, but high performance is still required.

In precision industries, even the slightest variation in flow can result in issues ranging from inaccurate measurements to malfunctioning machinery. The axial flow piston pump ensures that these variations are minimized, providing the steady and reliable fluid delivery necessary for tasks like precision calibration and high-accuracy hydraulic control systems.

The Role of Fixed Displacement Piston Pumps in Precision Applications

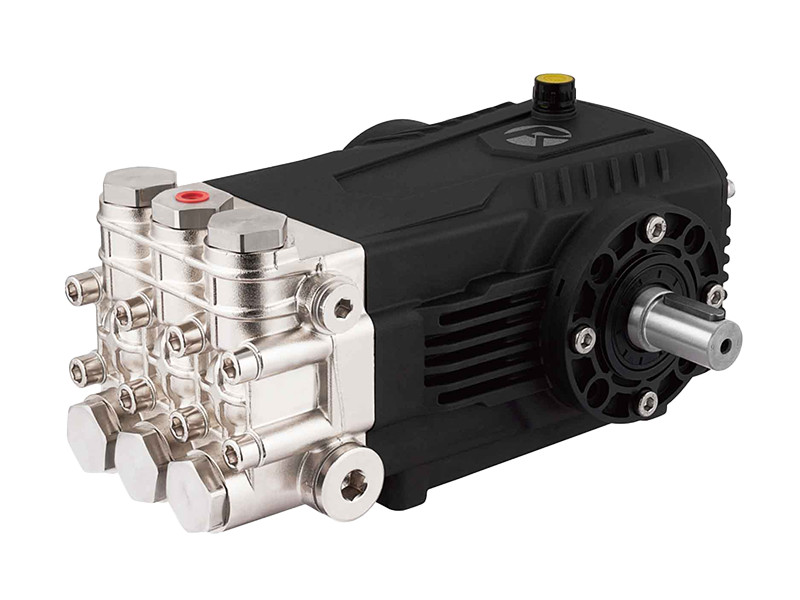

While axial flow piston pumps are ideal for high-precision tasks, it's also essential to consider other options, such as the fixed displacement piston pump. A fixed displacement piston pump moves a fixed volume of fluid with each stroke of the piston, meaning the amount of fluid displaced is constant, regardless of system pressure. This type of pump is particularly useful in systems where the flow needs to remain constant, but it does not offer the same level of control over flow rate as an axial flow piston pump.

The fixed displacement piston pump can be a good choice for certain precision applications, particularly those in which high flow rates are required under constant pressure. However, for industries that demand finer adjustments and the ability to operate across a range of pressures, the axial flow piston pump is often the better option. The variable flow capabilities and smoother flow output make it an essential tool in applications where precision is paramount.

Benefits of the Hydura Piston Pump

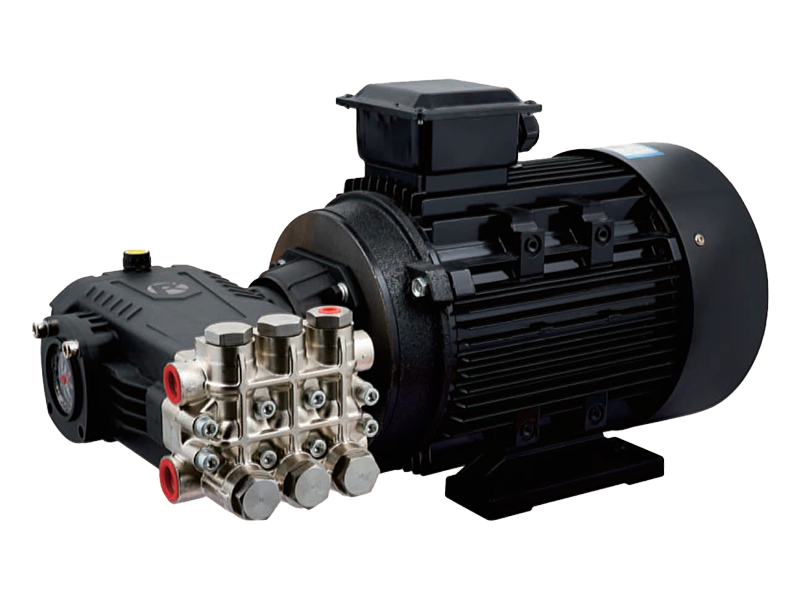

Another option worth considering in precision applications is the hydura piston pump. The hydura piston pump is known for its high reliability and efficiency, offering outstanding performance in hydraulic systems that require precise control over fluid movement. This type of pump is often used in systems where energy efficiency and long-term durability are important, making it a suitable choice for industrial applications that need to maintain constant performance over time.

Compared to the axial flow piston pump, the hydura piston pump typically offers greater endurance and better resistance to wear under high pressures, which can be beneficial in demanding environments where pump reliability is crucial. Additionally, hydura piston pumps tend to have a more robust design, making them suitable for heavier-duty tasks in industrial settings. However, in applications where precise control over the flow rate is more critical than raw durability, the axial flow piston pump may still be the outstanding choice due to its smoother, more consistent operation.

Key Considerations When Choosing an Axial Flow Piston Pump

1. Flow Control Requirements

One of important factors when selecting an axial flow piston pump is understanding your flow control requirements. Precision applications often demand a high level of control over the fluid flow rate. The axial flow piston pump excels in this area, as it can provide highly consistent flow while maintaining the desired pressure. This makes it an ideal choice for applications in laboratories, automotive testing, or manufacturing where precise fluid delivery is needed.

2. Pressure and Flow Range

For high-pressure systems, the axial flow piston pump can maintain consistent fluid delivery even under variable pressure conditions. In contrast, while the fixed displacement piston pump works well in fixed pressure systems, it might not offer the flexibility needed in applications where pressure fluctuations are common. The axial flow piston pump's ability to adjust to a range of pressures makes it a more adaptable choice for precision tasks.

3.System Size and Efficiency

Precision applications often involve systems that need to be compact yet highly efficient. The axial flow piston pump offers a high power-to-size ratio, meaning it can deliver exceptional performance without taking up too much space. This is particularly important in industries such as aerospace, where space constraints are significant, but high-performance standards must still be met.

4.Maintenance and Longevity

Pumps like the hydura piston pump are often chosen for their long lifespan and low maintenance requirements, which are important considerations in industrial environments. However, the axial flow piston pump can also be highly durable if properly maintained. It's essential to factor in the anticipated workload and operating conditions when making your choice, ensuring that the selected pump will provide reliable performance over time.

English

English Español

Español русский

русский