Effective Strategies to Prevent Cavitation in Three-Plunger High-Pressure Pumps

Understanding Cavitation in High-Pressure Pumps

Cavitation is a common and potentially damaging phenomenon affecting many types of pumps, including the Three Plunger High Pressure Pump. It occurs when vapor bubbles form in the liquid due to local drops in pressure and subsequently collapse, causing shockwaves that can erode pump components. This not only reduces pump efficiency but also causes costly repairs and downtime. Recognizing the causes and implementing effective prevention techniques is essential for maintaining pump reliability and longevity.

Causes of Cavitation in Three-Plunger High-Pressure Pumps

Cavitation typically arises when the pressure at the pump inlet falls below the vapor pressure of the fluid being pumped. Factors contributing to this include excessive suction lift, blocked or undersized suction lines, high fluid temperatures, and rapid changes in flow velocity. In the case of three plunger pumps, improper installation, incorrect pump sizing, or operating outside recommended conditions can increase cavitation risk. Understanding these factors helps operators take proactive measures.

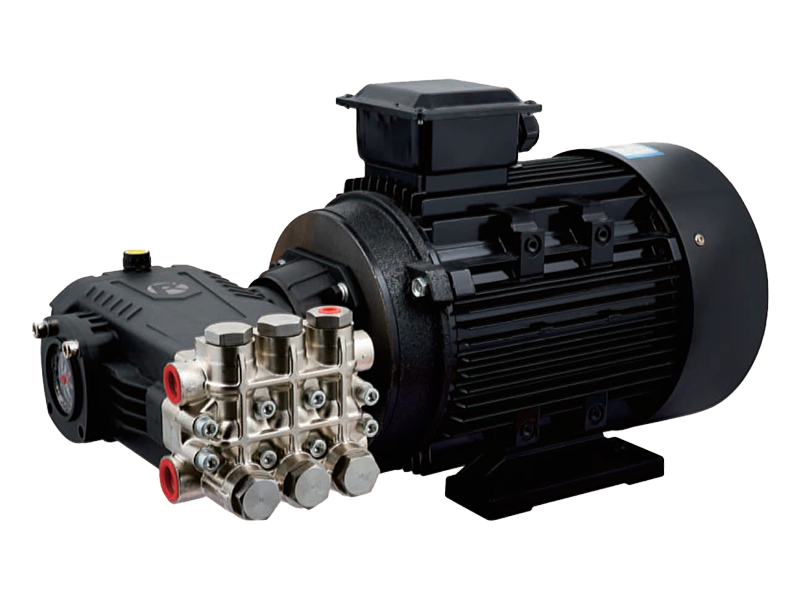

Proper Pump Selection and Installation

Selecting the right pump size and model based on the system’s flow and pressure requirements is vital to prevent cavitation. Oversized or undersized pumps can cause abnormal flow conditions that promote vapor bubble formation. Additionally, installing the pump at or below the fluid source level can reduce suction lift, thereby lowering the risk. Ensuring straight, adequately sized suction piping free from obstructions facilitates smooth fluid flow into the Three Plunger High Pressure Pump.

Controlling Fluid Temperature and Properties

Higher fluid temperatures reduce vapor pressure margins and increase cavitation risk. Monitoring and controlling fluid temperature within recommended limits helps maintain stable operation. In some cases, pre-cooling or insulation of piping may be necessary. Understanding the fluid’s properties, such as viscosity and vapor pressure, allows operators to anticipate cavitation potential and adjust operating parameters accordingly.

Regular Maintenance and Inspection

Routine maintenance is essential for early detection and prevention of cavitation damage. Inspecting suction strainers, filters, and valves ensures unobstructed fluid flow. Monitoring vibration and noise levels can also indicate cavitation onset. Addressing wear or damage promptly helps avoid escalation and preserves pump integrity.

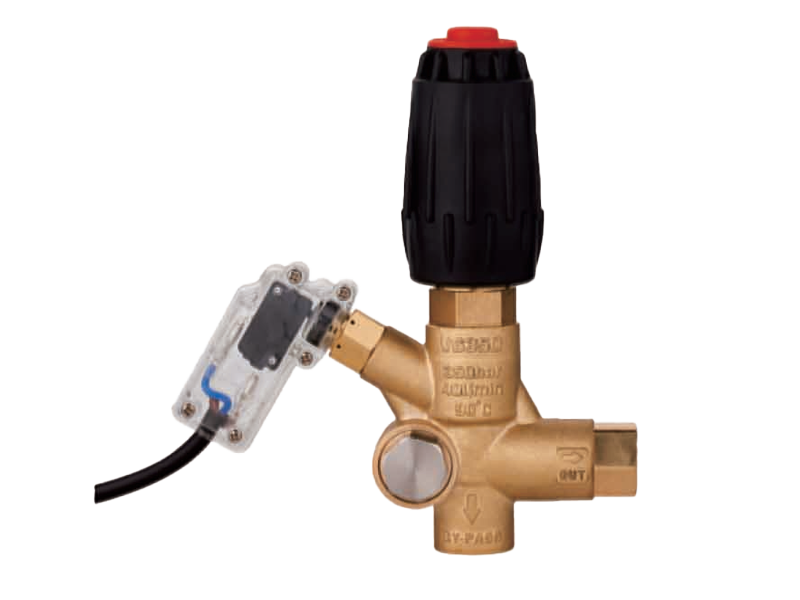

Utilizing Cavitation-Resistant Pump Components

Manufacturers often provide three-plunger high-pressure pump components designed to resist cavitation damage, such as hardened plungers, wear-resistant seals, and optimized valve designs. Using these enhanced parts extends pump life in challenging conditions. Additionally, installing flow control devices or surge tanks can smooth pressure fluctuations and reduce cavitation likelihood.

Operator Training and Process Optimization

Educating operators on cavitation causes, symptoms, and prevention techniques empowers proactive management. Adjusting operating parameters like flow rate and pressure to stay within recommended ranges optimizes pump performance and longevity. Incorporating automation and monitoring systems provides real-time alerts for abnormal conditions, enabling timely intervention.

Maintaining Efficiency by Preventing Cavitation in Three Plunger Pumps

Preventing cavitation in Three Plunger High Pressure Pumps requires a comprehensive approach involving proper pump selection, installation, operation, and maintenance. By ensuring adequate NPSH, controlling fluid parameters, and utilizing cavitation-resistant components, industries can protect their equipment from costly damage. Combined with operator training and monitoring, these strategies promote efficient, reliable pump performance over the long term.

English

English Español

Español русский

русский