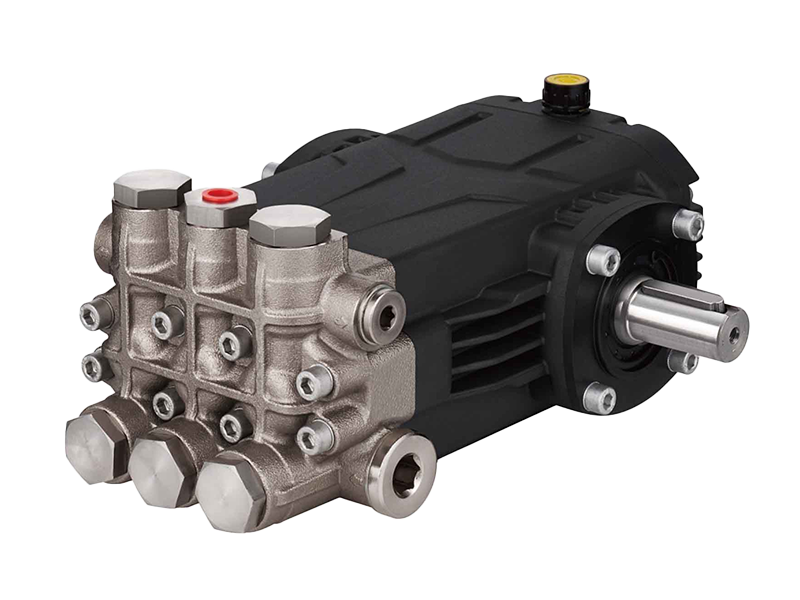

Ensuring Reliable Continuous Operation of Three Plunger High Pressure Pump

The Importance of Stability in Industrial Applications

High-pressure pumps are a cornerstone of many industrial processes, from chemical manufacturing and water treatment to oil and gas operations. In these settings, consistent performance during extended operation is critical to maintain efficiency, ensure safety, and prevent costly downtime. The Three Plunger High Pressure Pump has earned recognition for its robust design and ability to handle demanding tasks. However, operators often raise concerns about whether it can sustain stable pressure and flow rates during continuous use over long periods. Addressing these concerns requires an understanding of the pump’s design, materials, and maintenance requirements.

Structural Design for Performance Consistency

The Three Plunger High Pressure Pump features a three-plunger configuration that distributes pressure evenly across multiple pistons. This design reduces mechanical stress on individual components, minimizes vibration, and promotes smoother fluid flow. Even distribution of pressure is particularly important during continuous operation, as it prevents premature wear and reduces the risk of pressure fluctuations. Precision machining of the plunger sleeves, cylinder block, and valve seats ensures that tolerances are tight and consistent, further supporting long-term operational stability. The robust structural integrity of the pump housing is also critical, as it prevents deformation under high pressures and maintains alignment of moving components.

Material Selection and Durability

Materials play a significant role in maintaining stability during continuous operation. High-quality pumps utilize stainless steel, hardened alloys, and corrosion-resistant coatings for plungers, valves, and cylinder blocks. These materials resist wear, erosion, and chemical degradation, allowing the pump to function consistently even under abrasive or chemically aggressive fluids. Proper selection of sealing materials, such as PTFE or reinforced rubber, ensures leakage and maintains pressure over long operating cycles. By combining durable materials with precision engineering, the Three Plunger High Pressure Pump achieves consistent performance under continuous load.

Managing Thermal and Mechanical Stress

Continuous operation generates both thermal and mechanical stress on pump components. Heat buildup can affect metal expansion, viscosity of pumped fluids, and seal integrity, while repeated motion can cause wear on plungers and valves. To counteract these effects, high-pressure pumps often incorporate features such as oil lubrication systems, cooling jackets, or thermal monitoring devices. Maintaining proper operating conditions, including pressure, temperature, and flow rate within specified limits, is essential to prevent performance degradation. Proper alignment and secure mounting of the pump further reduce mechanical stress and vibration during extended operation.

Maintenance Strategies to Preserve Stability

Even the most well-designed pumps require routine maintenance to ensure reliable, continuous operation. Regular inspection of plungers, seals, and valves allows early detection of wear or potential failure points. Lubrication schedules and replacement intervals for high-wear components help maintain smooth motion and consistent pressure output. Monitoring pump performance, including flow rate, pressure consistency, and vibration levels, allows operators to identify and correct minor issues before they escalate. Adhering to manufacturer-recommended maintenance practices significantly extends the operational lifespan and stability of the pump.

Achieving Consistent Long-Term Performance

The Three Plunger High Pressure Pump is engineered to provide reliable performance during continuous operation. Its three-plunger configuration, precision construction, durable materials, and careful design considerations all contribute to stability, even under demanding industrial conditions. Proper management of thermal and mechanical stress, coupled with routine maintenance, ensures that the pump maintains consistent pressure and flow rates over extended periods. By understanding these factors and implementing practices, operators can improve efficiency, reduce downtime, and enjoy dependable performance from their high-pressure pumping systems.

English

English Español

Español русский

русский