Evaluating Wear and Leakage Risks in Three Plunger High Pressure Pump

Reliability and long-term performance are essential for any high-pressure pumping system. The Three Plunger High Pressure Pump is widely used for its ability to generate substantial pressures and maintain consistent flow rates. However, prolonged operation often raises concerns regarding component wear and potential leakage, which can compromise efficiency, safety, and operational continuity. Understanding the factors that contribute to wear and leakage, as well as strategies for maintenance, is critical for ensuring suitable pump performance over time.

Material Selection and Component Durability

The durability of a high-pressure pump largely depends on the materials used in its construction. High-quality pumps typically feature stainless steel or hardened alloy plungers, corrosion-resistant valves, and reinforced seals. These materials are designed to withstand high pressures and abrasive fluids, reducing the risk of premature wear. However, even with premium materials, repeated operation over months or years can gradually degrade components. The Three Plunger High Pressure Pump’s plunger design distributes pressure evenly across three pistons, which can mitigate wear compared to single-plunger systems, but it does not eliminate the need for regular inspection and maintenance.

Common Causes of Wear and Tear

Wear in a high-pressure pump can occur in multiple areas, including plungers, valves, seals, and bearings. Abrasive or particulate-laden fluids accelerate surface erosion, while excessive heat and insufficient lubrication can increase mechanical stress on moving components. Over time, repeated pressure cycles can cause seals to lose elasticity, causing leakage. Valve seats may also become pitted or eroded, reducing pumping efficiency and contributing to fluid loss. Recognizing these wear mechanisms helps operators implement preventive measures to prolong the service life of the pump.

Leakage Risks and Prevention

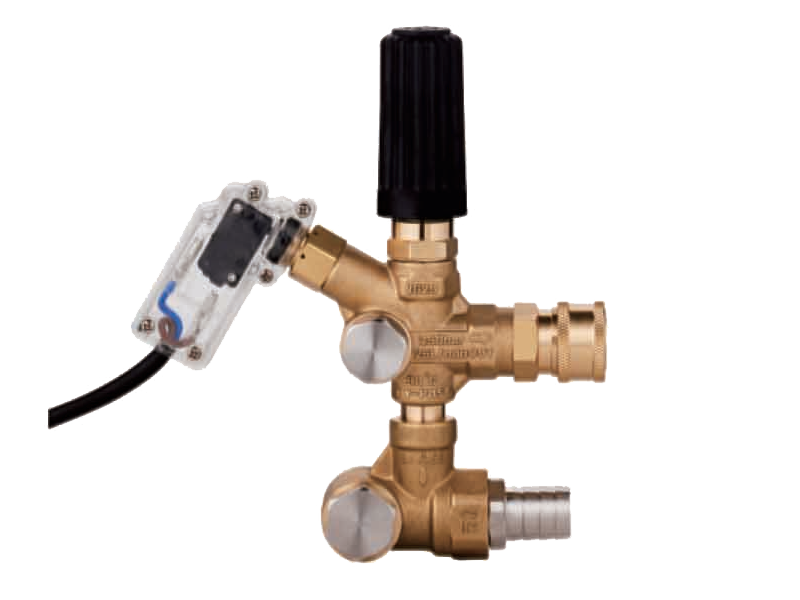

Leakage in a Three Plunger High Pressure Pump is typically associated with seal failure, valve wear, or improper assembly. Even minor leaks can reduce system pressure and cause fluid loss, posing operational and safety hazards. To prevent leakage, manufacturers recommend using high-quality sealing materials compatible with the pumped fluid, proper torque during assembly, and adherence to operating pressure limits. Regular inspection for early signs of wear, such as minor fluid seepage or unusual vibrations, allows operators to replace worn components before significant leakage occurs.

Maintenance Practices for Longevity

Preventive maintenance is key to reducing wear and leakage. Routine checks of seals, plungers, and valves, along with proper lubrication, can significantly extend the lifespan of a Three Plunger High Pressure Pump. Implementing scheduled replacement intervals for high-wear components ensures consistent performance. Additionally, maintaining fluid cleanliness and monitoring operating conditions, such as temperature and pressure, reduces stress on internal parts. Following manufacturer-recommended maintenance protocols not only preserves pump integrity but also optimizes operational efficiency and safety.

Balancing Performance and Reliability

The Three Plunger High Pressure Pump is a robust and reliable option for high-pressure applications, but like any mechanical system, it is subject to wear and potential leakage over time. Material quality, operating conditions, and maintenance practices all influence long-term durability. By understanding the factors that contribute to component degradation and implementing regular preventive maintenance, operators can ensure that the pump continues to perform efficiently while reducing the risk of wear-related failures or leaks. Proper care and inspection are essential for improving the service life and safety of high-pressure pumping systems.

English

English Español

Español русский

русский