How Do Marine Gear Pumps Withstand Saltwater and Harsh Ocean Conditions?

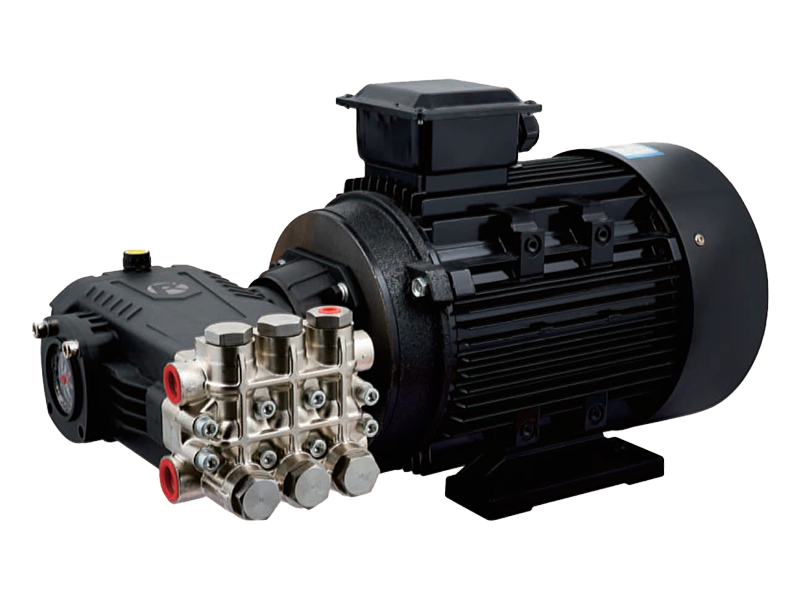

Marine environments are among the harshest for any machinery, with saltwater and corrosive conditions taking a toll on equipment. Marine gear pumps, a crucial component in the maritime industry, are designed to thrive under these conditions. These pumps, alongside chemical gear pumps and industrial gear pumps, must endure a barrage of challenges to maintain operational efficiency.

This article delves into how marine gear pumps are engineered to withstand saltwater corrosion and the relentless demands of oceanic operations.

Marine gear pumps are engineered with materials that can resist the corrosive effects of saltwater. The selection of materials is critical, as the marine environment is notorious for its ability to corrode metal surfaces. Chemical gear pumps, which are often used in applications involving aggressive chemicals, share similar material requirements to those of marine gear pumps. Both types of pumps are constructed with materials that can handle the corrosive nature of their respective environments without succumbing to deterioration.

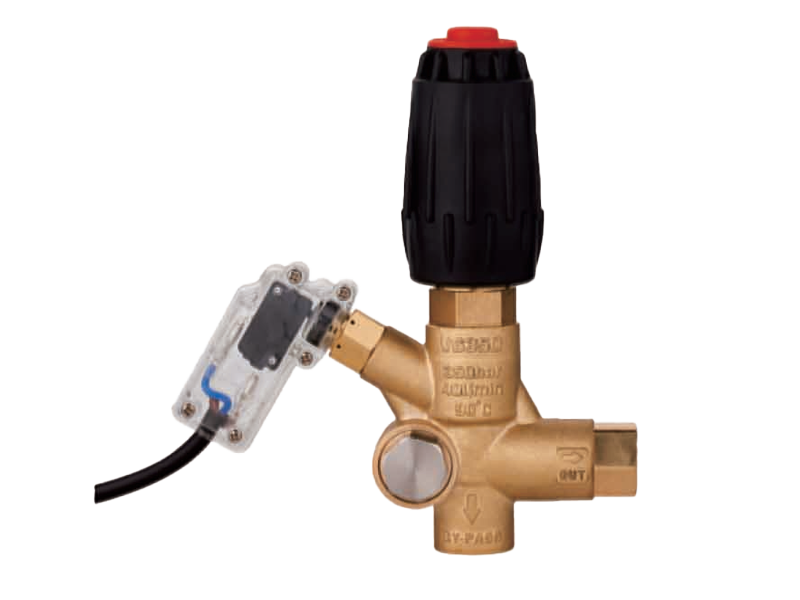

The design of marine gear pumps also incorporates features that protect against the ingress of saltwater and debris. Unlike industrial gear pumps, which may be designed for less demanding environments, marine gear pumps require seals and protective barriers to prevent the intrusion of water and other contaminants. This is essential for maintaining the pump's performance and longevity, as saltwater can cause rapid wear and corrosion if it comes into direct contact with the pump's internal components.

In harsh ocean conditions, the reliability of marine gear pumps is paramount. These pumps must operate continuously, often under load, without fail. Chemical gear pumps and industrial gear pumps may also face demanding conditions, but the marine gear pump's resilience is tested by the relentless motion of waves and the corrosive nature of saltwater. To ensure reliability, marine gear pumps are often equipped with self-priming capabilities and robust construction that can handle the vibrations and impacts associated with maritime operations.

Maintenance is a key aspect of marine gear pump longevity. Regular inspection and servicing are essential to keep these pumps running smoothly. Unlike chemical gear pumps, which may require special cleaning procedures to remove chemical residue, marine gear pumps need thorough cleaning to remove salt buildup and other debris. Industrial gear pumps may also require maintenance, but the frequency and intensity may vary depending on the application.

The efficiency of marine gear pumps is another area where they excel. These pumps are designed to maintain a high level of performance even when operating in the challenging conditions of the sea. Chemical gear pumps and industrial gear pumps may also prioritize efficiency, but the marine gear pump's efficiency is critical for the operation of vessels and offshore platforms, where downtime can be costly.

In conclusion, marine gear pumps are a testament to engineering resilience in the face of harsh ocean conditions. Their design, materials, and maintenance routines are all tailored to withstand the corrosive effects of saltwater and the relentless forces of the sea. By understanding the unique challenges faced by marine gear pumps, chemical gear pumps, and industrial gear pumps, engineers can ensure that these vital components continue to perform reliably in their respective environments.

English

English Español

Español русский

русский