Why Triplex Water Pumps Are great for Consistent and High-Pressure Water Delivery Systems

Unlike single or dual-piston designs, these robust systems utilize three plungers working in great synchronization to deliver smooth, uninterrupted water flow at high pressures. From industrial cleaning to agricultural irrigation, the triplex reciprocating pump design solves the pulsation and reliability issues that plague simpler pump technologies. When integrated into professional-grade equipment like a triplex plunger pressure washer, these pumps demonstrate why they've become indispensable for demanding applications.

At the heart of every triplex water pump lies a precision-engineered system that sets it apart from conventional pumps. The magic happens through three key design features:

1. Three-Plunger Configuration: Unlike single-piston pumps that create noticeable pressure surges, the triplex reciprocating pump uses three plungers operating 120 degrees out of phase. This creates near-constant water flow with minimal pulsation - a critical factor when powering sensitive equipment.

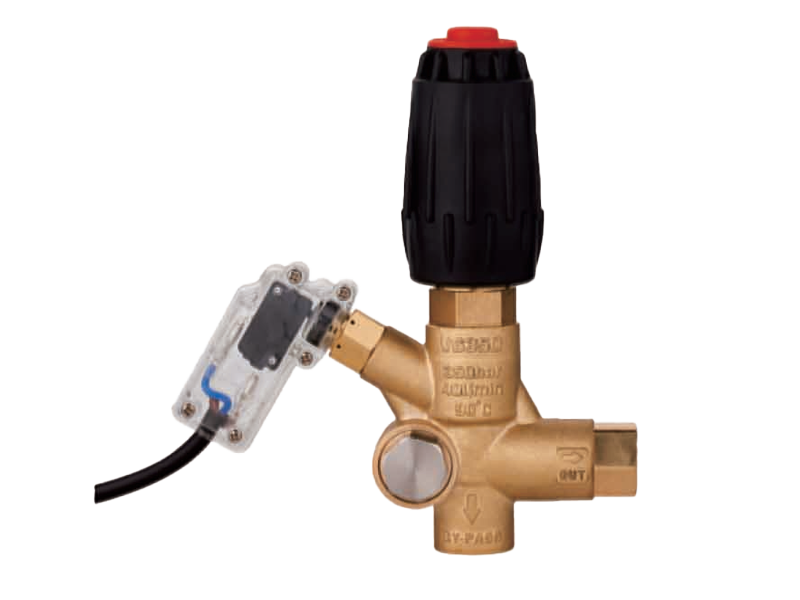

2. Heavy-Duty Construction: Industrial-grade triplex plunger pressure washer models feature hardened steel crankshafts, ceramic plungers, and brass manifolds that withstand years of continuous operation at pressures exceeding 5,000 PSI.

3. Optimized Fluid Dynamics: The carefully engineered intake and discharge valves in a triplex water pump minimize turbulence and cavitation, protecting the pump from damage while improving efficiency.

Several industries have come to rely on triplex reciprocating pump technology for their most demanding water delivery needs:

- Industrial Cleaning: Professional triplex plunger pressure washer units are the preferred choice for shipyards, refineries, and manufacturing plants where cleaning downtime costs thousands per hour.

- Agriculture: Large-scale irrigation systems use triplex water pump technology to maintain consistent pressure across vast fields with varying elevation changes.

- Mining: De-watering operations depend on the continuous operation that only a triplex reciprocating pump can provide in remote, harsh environments.

- Municipal Services: Fire departments and public works agencies trust triplex plunger pressure washer systems for critical infrastructure maintenance where reliability can't be compromised.

When compared to other high-pressure pump technologies, the triplex water pump offers distinct benefits:

1. Smoother Flow Characteristics: The three-cylinder design of a triplex reciprocating pump reduces pulsation by over 80% compared to duplex pumps, protecting downstream equipment from vibration damage.

2. Higher Pressure Capability: While axial pumps struggle beyond 3,000 PSI, industrial triplex plunger pressure washer systems routinely operate at 5,000-10,000 PSI for specialized cleaning applications.

3. Longer Service Life: The balanced load distribution across three plungers means a triplex water pump typically lasts 3-5 times longer than comparable duplex models before requiring rebuilds.

4. Energy Efficiency: Advanced triplex reciprocating pump designs can achieve 92% or better mechanical efficiency, significantly reducing power consumption for high-pressure applications.

While triplex plunger pressure washer systems are remarkably durable, proper care ensures improve lifespan:

- Regular Oil Changes: Most triplex water pump manufacturers recommend oil changes every 500 operating hours or quarterly for continuous-use applications.

- Valve Inspection: The suction and discharge valves in a triplex reciprocating pump should be checked every 1,000 hours for wear or mineral buildup.

- Plunger Replacement: Ceramic plungers in professional triplex plunger pressure washer units typically last 5,000-8,000 hours before needing replacement.

- Winterization: Proper fluid drainage prevents freeze damage when triplex water pump systems are stored in cold environments.

From industrial cleaning to critical water delivery systems, the triplex reciprocating pump has proven itself as reliable solution for high-pressure applications. Its three-cylinder design eliminates the pulsation and reliability issues of simpler pumps, while delivering unmatched durability and efficiency. Whether you're operating a professional triplex plunger pressure washer or maintaining a large-scale water delivery system, investing in triplex water pump technology ensures consistent performance when it matters most. As industries continue demanding higher pressures and greater reliability, triplex pump technology will remain at the forefront of fluid handling solutions.

English

English Español

Español русский

русский