How to Select the Right Industrial Hydraulic Pump for Heavy-Duty Applications?

Whether you are working with hydraulic presses, excavators, or other heavy machinery, the hydraulic pump serves as the heart of the system, converting mechanical energy into hydraulic energy to drive various functions.

1. Understanding Your Application Requirements

step in selecting the right industrial hydraulic pump is to clearly understand the specific requirements of your application. Key factors to consider include:

- improve Operating Pressure: Determine high pressure your system will need to handle. For example, some heavy-duty applications may require pressures up to 700 bar.

- Flow Rate: Assess the volume of hydraulic fluid your system needs to move. Flow rates can vary widely, from a few liters per minute to over 100 liters per minute.

- Operating Speed: Consider the speed at which the pump will operate. This can range from 500 rpm to over 3,000 rpm, depending on the application.

- Power Source: Decide whether you need an electrically powered pump or one driven by an internal combustion engine. Electric hydraulic pumps are often preferred for their efficiency and ease of use.

2. Choosing the Right Type of Hydraulic Pump

There are several types of hydraulic pumps available, each with its own set of advantages and ideal applications:

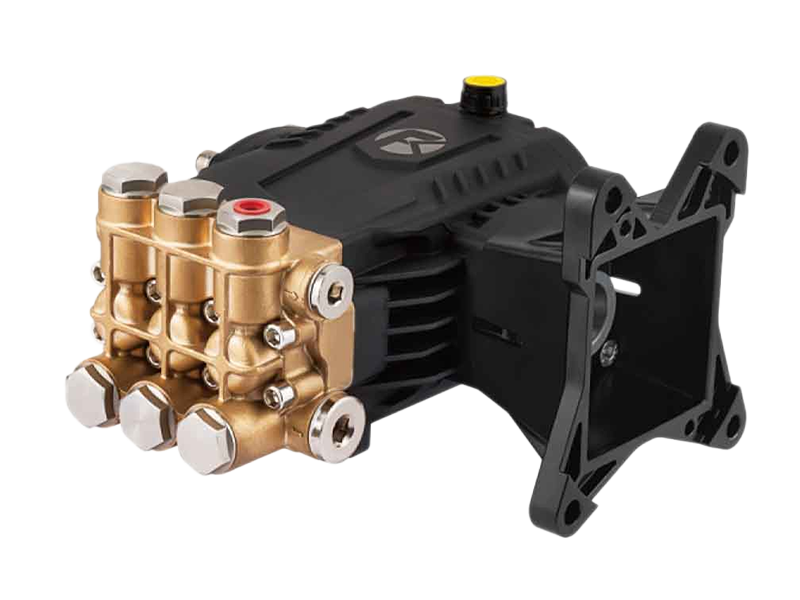

#Hydraulic Piston Pumps

Hydraulic piston pumps are highly efficient and capable of generating very high pressures, making them ideal for heavy-duty applications such as excavators and cranes. These pumps use a plunger-like mechanism to transfer hydraulic fluid and can achieve pressures up to 1,500 bar. They are also known for their durability and ability to handle high flow rates.

#Hydraulic Gear Pumps

Hydraulic gear pumps are simpler in design and often used in applications requiring lower pressures and flow rates. They are known for their reliability and ease of maintenance. Gear pumps can operate at pressures up to 310 bar and are suitable for applications such as lubrication systems and low-pressure hydraulic circuits.

#Hydraulic Vane Pumps

Vane pumps are known for their smooth operation and ability to handle a wide range of viscosities. They are often used in applications where noise reduction is important, such as in industrial presses and machine tools. These pumps can operate at pressures up to 210 bar and offer high efficiency with minimal pulsation.

3. Material Considerations

The material of the hydraulic pump is another important factor to consider. Stainless steel hydraulic pumps are highly durable and resistant to corrosion, making them ideal for applications involving harsh chemicals or environments. These pumps are also preferred for their longevity and ability to withstand continuous use in demanding conditions.

4. Additional Features and Considerations

- Pump Pressure Regulator Valve: Many industrial hydraulic pumps come equipped with pressure regulator valves to maintain consistent pressure and prevent system damage. These valves can be adjusted to match the specific pressure requirements of your application.

- Efficiency and Energy Savings: Modern hydraulic pumps are designed to be highly efficient, reducing energy consumption and operating costs. Look for pumps with advanced control systems and variable speed drives to optimize performance.

- Maintenance and Support: Consider the availability of spare parts and technical support from the manufacturer. Reliable support can significantly reduce downtime and maintenance costs.

Selecting the right industrial hydraulic pump for heavy-duty applications involves understanding your specific requirements, choosing the appropriate type of pump, and considering material and additional features. By carefully evaluating these factors, you can ensure that your hydraulic system operates efficiently and reliably, reducing maintenance costs and improving productivity. Whether you opt for a hydraulic piston pump, gear pump, or vane pump, always prioritize quality and compatibility with your application to achieve results.

English

English Español

Español русский

русский