Performance of Stainless Steel Pumps with High-Viscosity Fluids

High-Viscosity Fluid Handling

Pumping high-viscosity fluids, such as slurries, pastes, or oils, requires specialized equipment that can maintain flow without excessive energy consumption or mechanical stress. The Stainless Steel Pump is often selected for these applications due to its durability, corrosion resistance, and ability to handle challenging fluids. Understanding how these pumps perform under high-viscosity conditions helps operators optimize efficiency and prevent operational issues.

Impact of Viscosity on Pump Performance

High-viscosity fluids create greater resistance to flow compared to low-viscosity liquids. This increased resistance requires more torque from the pump motor to maintain the desired flow rate. In a Stainless Steel Pump, the impeller must overcome both the fluid’s internal friction and the resistance caused by narrow passages within the pump casing. If the pump is not designed for high-viscosity operation, this can cause reduced flow, higher energy consumption, and potential overheating of mechanical components.

Pump Design Considerations for Viscous Fluids

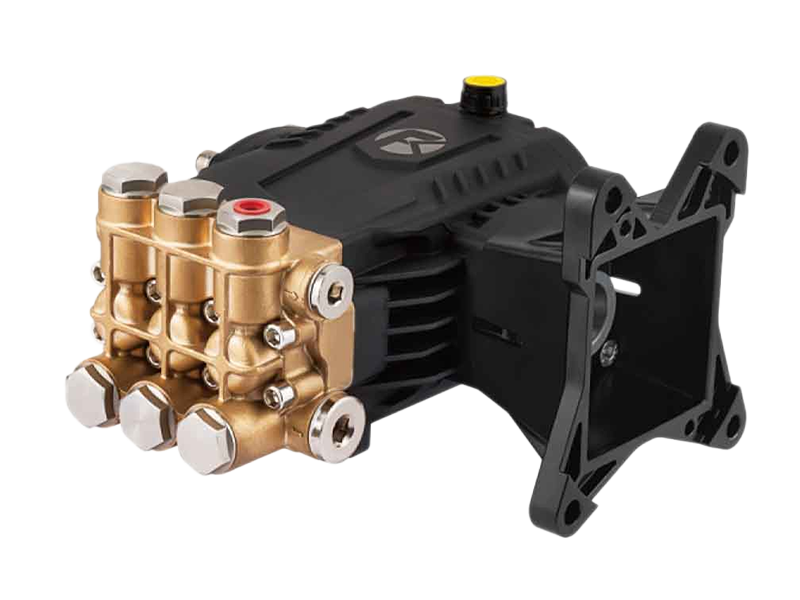

Specific design features enhance the ability of stainless steel pumps to handle viscous media effectively. Pumps with larger clearances, robust impeller designs, and wider flow channels reduce resistance and allow the fluid to pass smoothly. Positive displacement designs, including gear pumps, lobe pumps, or progressive cavity pumps, are often preferred for very viscous fluids because they maintain a constant flow regardless of viscosity changes. Proper selection of impeller type and casing material ensures efficient operation and prolongs service life.

Material Advantages of Stainless Steel

The use of stainless steel in pump construction provides important benefits for high-viscosity fluid applications. Stainless steel offers good mechanical strength and resists chemical degradation from viscous or corrosive liquids. It also tolerates higher operational pressures and temperatures compared to many alternative materials, making it suitable for demanding industrial processes. The smooth surface finish of stainless steel reduces friction and adhesion of sticky substances, further improving pump efficiency and reducing maintenance frequency.

Operational Strategies for Optimal Performance

When handling viscous fluids, operators must adjust operational parameters to maintain suitable performance. Reducing flow velocity, controlling temperature to decrease viscosity, and ensuring the pump is adequately primed can help maintain consistent discharge. Regular monitoring of torque, motor load, and pressure ensures the pump is operating within safe limits. Preheating viscous fluids or using diluents may also be necessary for extremely thick liquids to facilitate smoother flow and reduce stress on the pump components.

Applications and Industrial Use

Stainless Steel Pumps designed for high-viscosity fluids are widely used in food processing, chemical manufacturing, pharmaceuticals, and wastewater treatment. They are capable of pumping substances such as syrups, oils, sludges, and polymer solutions. By combining corrosion resistance with mechanical strength, stainless steel pumps provide reliable operation under conditions that would challenge pumps made from less durable materials.

Effective Handling of Viscous Liquids

A Stainless Steel Pump can handle high-viscosity fluids effectively when properly selected and maintained. Design considerations, material advantages, and operational strategies are critical to ensuring reliable performance. By addressing the unique challenges of viscous fluid pumping, stainless steel pumps provide durable, efficient, and safe solutions for demanding industrial applications, balancing flow consistency, energy consumption, and long-term reliability.

English

English Español

Español русский

русский