Safety with Pressure and Overload Protection in Three Plunger High Pressure Pump

The Importance of Safety Features

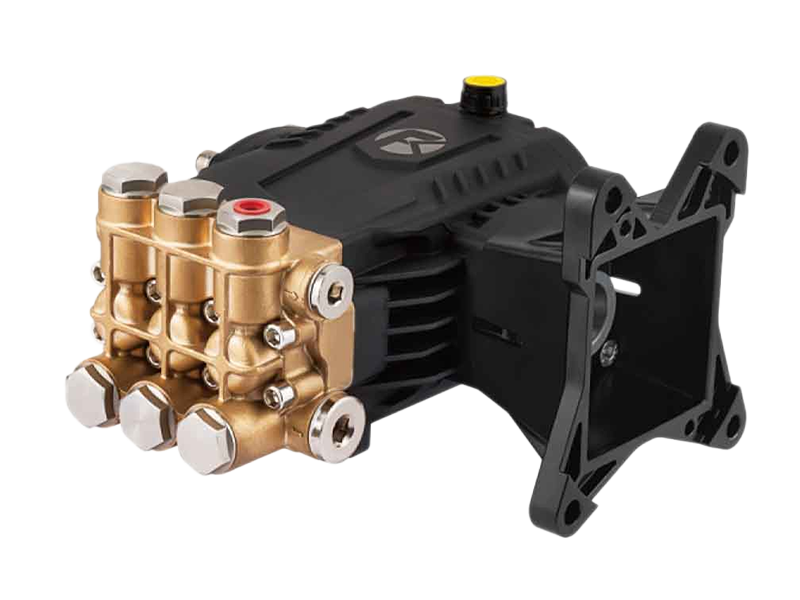

High-pressure pumps are essential in numerous industrial applications, including water treatment, chemical processing, and oil extraction. While performance and efficiency are critical, safety features such as pressure protection and overload safeguards are equally important. The Three Plunger High Pressure Pump is designed to operate under demanding conditions, and without proper protection, excessive pressure or mechanical overload can damage the pump, compromise system integrity, and create safety hazards. Understanding the built-in protective mechanisms is key to safe and reliable operation.

Pressure Protection Mechanisms

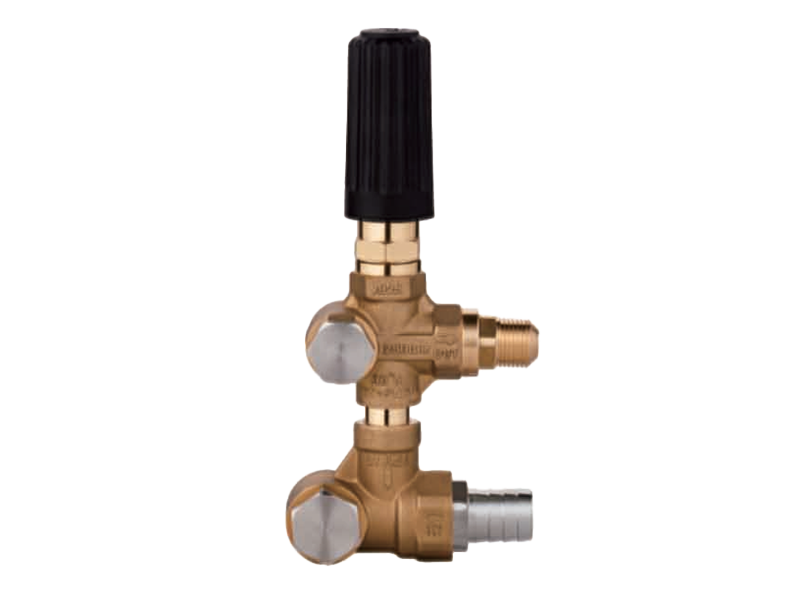

Pressure protection is essential to prevent damage caused by overpressure within the pump or the connected piping system. The Three Plunger High Pressure Pump is typically equipped with pressure relief valves or bypass systems that activate when pressure exceeds a predetermined limit. These devices divert fluid flow or release pressure to protect the pump components, including plungers, seals, and valves. By maintaining pressure within safe operational ranges, these mechanisms prevent mechanical failure and reduce the risk of leakage or rupture, ensuring that the pump continues to function reliably under varying system demands.

Overload Protection Features

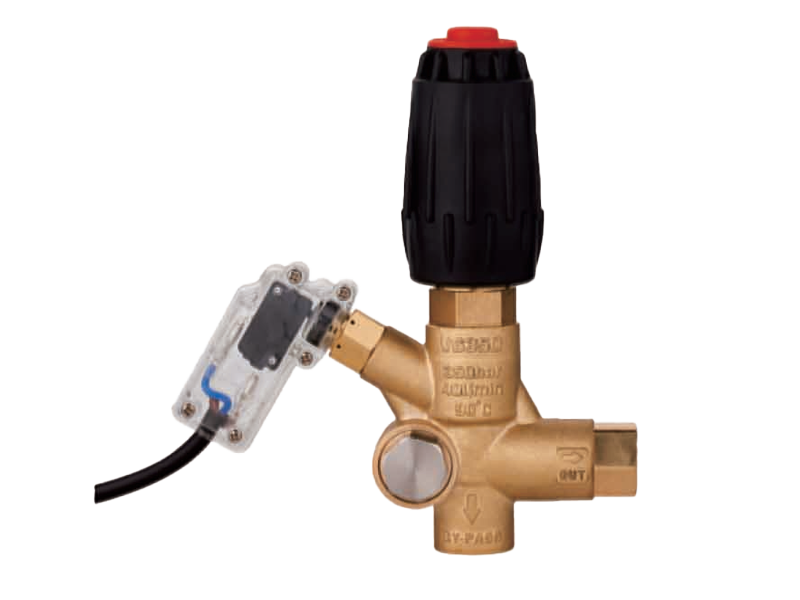

Overload protection safeguards the pump against excessive mechanical stress that can occur during high-load operation. Situations such as pumping highly viscous fluids, encountering blockages, or operating at pressures beyond design limits can increase mechanical load on plungers, bearings, and the drive system. The Three Plunger High Pressure Pump may incorporate features such as torque limiters, motor overload sensors, or automatic shutdown systems to detect abnormal loads. These devices prevent catastrophic failure by halting operation or reducing load until safe conditions are restored, thereby prolonging pump lifespan and protecting connected equipment.

Combined Safety Strategies

Effective operation requires integrating both pressure and overload protection systems. Pressure relief valves work in tandem with mechanical or electrical overload safeguards to ensure comprehensive protection. For example, if a pressure spike occurs due to downstream blockage, the relief valve opens to reduce pressure, while an overload sensor may simultaneously detect increased torque on the drive system and adjust motor input. This combination reduces the likelihood of failure, maintains stable operation, and protects both the pump and personnel.

Operational Practices

Even with built-in protection, operators must follow practices to ensure long-term safety and efficiency. Regular inspection of pressure relief valves, seals, and sensors is crucial to verify proper function. Maintaining clean and appropriate fluid media prevents blockages and excessive load on the pump. Monitoring system pressure and load trends helps detect potential issues early, allowing preventive action before safety mechanisms are triggered. Adhering to manufacturer guidelines regarding operating pressures, fluid types, and maintenance schedules is essential for safe, continuous operation.

Enhancing Reliability and Safety

Pressure and overload protection are critical features for ensuring the safe and reliable operation of the Three Plunger High Pressure Pump. By incorporating relief valves, torque limiters, and monitoring systems, the pump is safeguarded against excessive pressure and mechanical overload. Coupled with proper operational practices and routine maintenance, these protective features allow the pump to perform efficiently while reducing the risk of damage and ensuring personnel safety. Understanding and utilizing these safety mechanisms is essential for improving both the longevity and reliability of high-pressure pumping systems.

English

English Español

Español русский

русский