Sealing Systems and Leak Prevention in Pumps

Introduction to High-Pressure Pump Seals

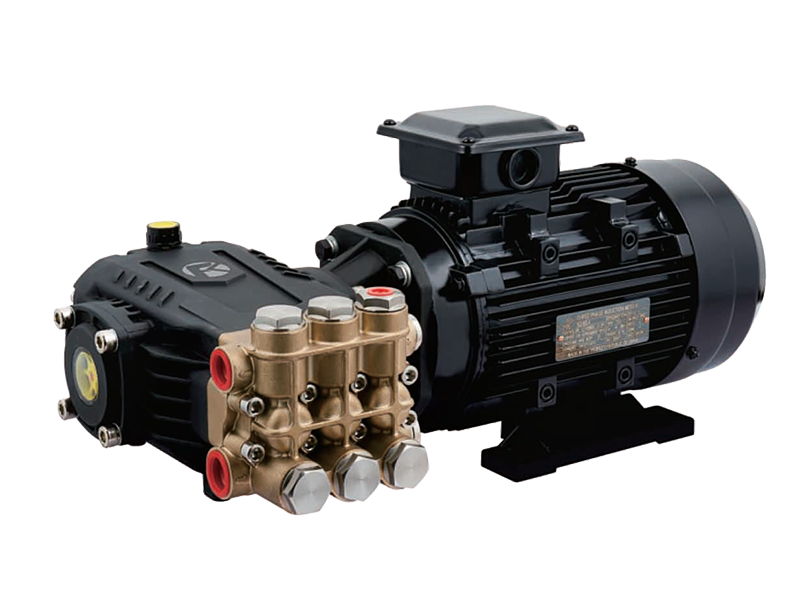

The Three Plunger High Pressure Pump is widely used in industrial cleaning, water treatment, and hydraulic systems due to its ability to deliver high pressure with consistent flow. A critical component of its design is the sealing system, which ensures that the pump maintains pressure, prevents fluid leakage, and operates efficiently. Understanding the types of seals and proper leak prevention methods is essential for safe and reliable pump operation.

Packing Seals

Packing seals are one of old and common sealing methods used in high-pressure pumps. They consist of a series of rings made from materials such as PTFE or braided graphite that are compressed around the pump shaft. Proper installation and regular adjustment are necessary to maintain an effective seal. Over-tightening can increase friction and wear, while loose packing can cause leakage. Routine inspection and replacement of worn packing rings help maintain pump performance and extend the service life of the Three Plunger High Pressure Pump.

Mechanical Seals

Mechanical seals provide a more advanced solution compared to traditional packing. They consist of two flat surfaces, one stationary and one rotating, pressed together to form a seal. These seals are highly effective in preventing leakage and can handle high-pressure environments with maintenance. Mechanical seals also reduce friction and energy consumption, improving overall pump efficiency. Proper alignment and careful handling during installation are crucial, as misalignment can cause premature wear or seal failure.

Lip Seals and O-Rings

Lip seals and O-rings are commonly used in certain sections of the pump, such as at the plunger or valve interfaces. These elastomeric components provide additional sealing against leakage, particularly in areas where the fluid is under lower pressure but still requires protection. Selecting materials compatible with the pumped fluid and temperature is essential. For example, nitrile rubber is often used for water-based applications, while Viton or EPDM may be preferred for chemical fluids or higher temperatures.

Preventing Leakage

Preventing leakage in a Three Plunger High Pressure Pump requires a combination of proper seal selection, installation, and maintenance. Regular inspection of all sealing components is necessary to identify wear, cracks, or material degradation before leaks occur. Maintaining clean fluid without abrasive particles helps prevent damage to seals and prolongs their life. Additionally, using the correct torque settings and ensuring precise alignment during assembly reduces stress on seals and reduces leakage risk. Following manufacturer guidelines for operating pressures and temperatures further ensures that the sealing system performs as intended.

Routine Maintenance Practices

Routine maintenance plays a vital role in leak prevention. Scheduled replacement of packing rings, mechanical seals, and O-rings prevents unexpected failures. Lubricating seals when required and flushing the pump to remove sediment or debris also protects the sealing system. Proper training of operators to recognize early signs of seal wear, such as minor drips or pressure fluctuations, allows timely corrective action and avoids costly downtime.

Sealing systems in a Three Plunger High Pressure Pump include packing seals, mechanical seals, and elastomeric components like O-rings and lip seals. Each type serves a specific purpose in preventing leakage and maintaining efficient operation. Effective leak prevention relies on selecting the right seal for the application, installing it correctly, and performing regular maintenance. By following practices, operators can ensure long-lasting performance, reduce maintenance costs, and maintain safe, reliable high-pressure pump operation.

English

English Español

Español русский

русский