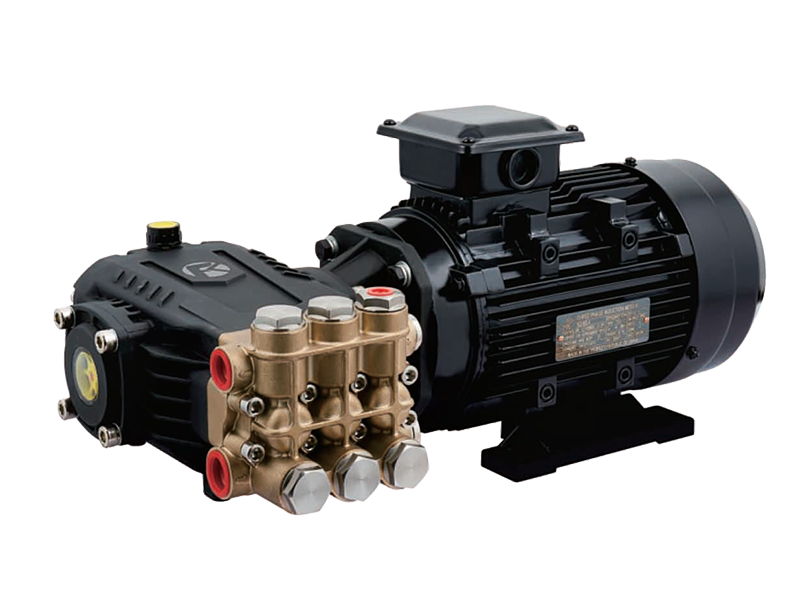

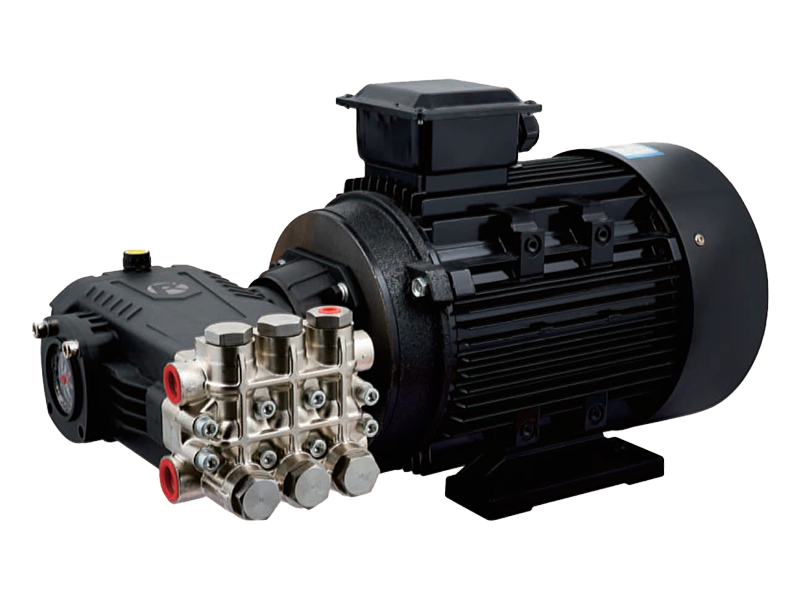

Sale Pump With Motor

In the realm of machinery, the union of pump and motor is an indispensable force, driving various vehicles and equipment with precision and power. At our company, we specialize in offering top-of-the-line pumps integrated seamlessly with motors, delivering unparalleled performance across a myriad of applications.

Key Features

1. Seamless Integration

At the heart of our pump with motor systems lies the seamless integration of the pump and motor components. Through meticulous engineering, we ensure that the pump is directly connected to the motor, optimizing efficiency and minimizing energy loss. This seamless integration results in smooth operation and enhanced performance across various machinery applications.

2. Versatility and Compatibility

Our pump with motor systems are designed to be versatile and compatible with a wide range of motor vehicles, engineering vehicles, and agricultural machinery. Whether it's washing cars, operating bulldozers, or powering concrete mixers and tractors, our systems provide reliable performance in diverse environments and applications.

3. Robust Construction

Durability is a hallmark of our pump with motor systems. Constructed from high-quality materials and engineered to withstand demanding conditions, our systems are built to last. From heavy-duty construction sites to rigorous agricultural settings, our robust systems deliver consistent performance and reliability.

Advantages

1. Enhanced Efficiency

By directly coupling the pump with the motor, our systems eliminate the need for additional transmission components, reducing energy loss and increasing overall efficiency. This enhanced efficiency translates to lower operational costs and improved productivity, making our systems a cost-effective solution for various applications.

2. Reduced Maintenance Requirements

The seamless integration of the pump with the motor minimizes wear and tear on components, resulting in reduced maintenance requirements. With fewer moving parts and simplified operation, our systems offer hassle-free maintenance, allowing operators to focus on their tasks without interruptions.

3. Precision Performance

Our pump with motor systems are engineered for precision performance, delivering consistent flow rates and pressure levels. Whether it's delivering water for irrigation or powering hydraulic systems, our systems ensure precise control and reliable operation, contributing to performance in diverse applications.

Applications

1. Agricultural Machinery

Our pump with motor systems are widely used in agricultural machinery for tasks such as irrigation, spraying, and fluid transfer. From tractors to combine harvesters, our systems provide the necessary power and performance to keep agricultural operations running smoothly and efficiently.

2. Construction Equipment

In the construction industry, our systems play a vital role in powering various equipment, including concrete mixers, bulldozers, and excavators. With their robust construction and seamless integration, our systems withstand the rigors of construction sites and deliver reliable performance under demanding conditions.

3. Automotive Service Centers

Automotive service centers rely on our pump with motor systems for tasks such as car washing, fluid transfer, and hydraulic system operation. With their versatility and compatibility, our systems provide automotive professionals with the power and efficiency they need to maintain and service vehicles effectively.

At our company, we take pride in offering top-quality pump with motor systems that deliver unmatched performance, efficiency, and reliability. Whether you're in agriculture, construction, or automotive services, our systems are the ideal choice for powering your machinery and equipment. With seamless integration, robust construction, and precision performance, our systems are engineered to exceed your expectations and drive success in your operations.

English

English Español

Español русский

русский

一种可调节的安全阀1.jpg)

高压泵kt2250.jpg)

1.jpg)

2.jpg)