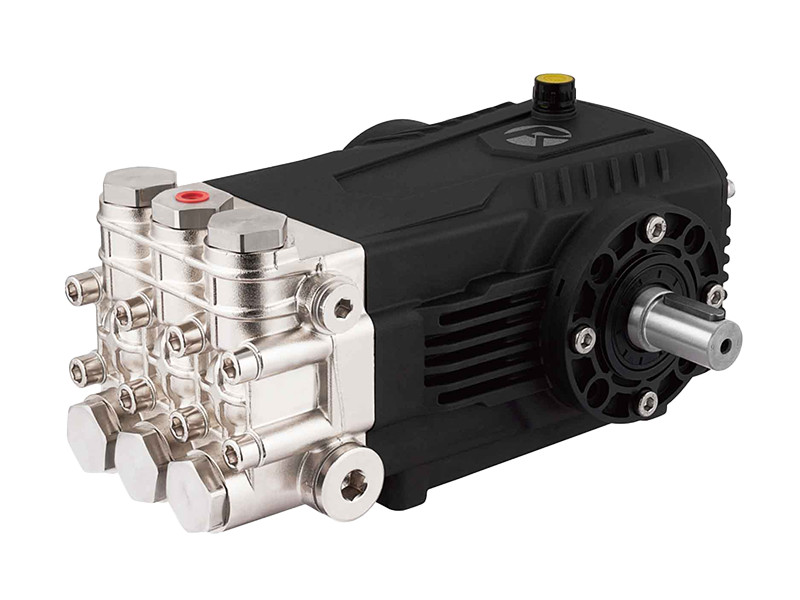

FKB-N(Nickel)Regular Pump

3-piston alternating volumetric pumps for use on cleaning units and industrial systems. It can be coupled to various types of motors, directly or with...

The FKB series stands as a testament to our commitment to excellence in pumping technology. These 3-piston alternating volumetric pumps are meticulously crafted for performance in both cleaning units and industrial systems. Designed with precision and durability in mind, the FKB series offers a range of features that set it apart in the market.

Product Advantages:

1. Flexible Compatibility

- The FKB series pumps are engineered to seamlessly integrate with various types of motors, offering unparalleled versatility in system design.

- Whether coupled directly or with a flexible joint, our pumps ensure smooth operation and compatibility with different power sources.

2. Robust Construction

- Crafted with a pump body and cover made from die-cast aluminum alloy, the FKB series boasts exceptional durability to withstand the rigors of industrial applications.

- Featuring oversized friction bearings and a pump shaft forged from pressed high-strength steel, these pumps are built to last, delivering reliable performance even in demanding environments.

3. Efficient Design

- The FKB series incorporates a crank-connecting rod mechanism to drive its pistons, ensuring efficient and consistent fluid delivery with minimal energy consumption.

- With one-piece ceramic pistons and a double gasket sealing system, our pumps guarantee leak-free operation and reduced maintenance requirements, uptime and productivity.

Product Features:

1. Optimized Performance

- Engineered for precision, the FKB series pumps deliver high-pressure output and precise flow control, making them ideal for a wide range of industrial applications.

- The pump head, constructed from pressed brass, ensures smooth fluid flow and minimizes pressure loss, the efficiency of your systems.

2. User-Friendly Design

- Designed with ease of maintenance in mind, the FKB series pumps feature intake and delivery valves with plugs, facilitating quick and hassle-free servicing.

- The inclusion of a rear cover with an oil drain outlet enhances accessibility, allowing for convenient oil changes and prolonging the lifespan of the pump components.

3. Versatile Applications

- From cleaning units to industrial systems, the FKB series pumps find applications across diverse industries, including automotive, manufacturing, and agriculture.

- Whether used for high-pressure cleaning, fluid transfer, or chemical dosing, our pumps deliver consistent performance and reliability, meeting the unique needs of each application.

Product Applications:

1. Industrial Cleaning

- Our FKB series pumps excel in industrial cleaning applications, providing the high-pressure output required for effective surface cleaning and preparation.

- Whether removing grease, paint, or debris, our pumps deliver unmatched performance, enhancing productivity and efficiency in cleaning operations.

2. Fluid Transfer

- With their precise flow control and robust construction, FKB series pumps are ideal for fluid transfer tasks in manufacturing plants and processing facilities.

- From transferring chemicals and lubricants to circulating coolant and hydraulic fluids, our pumps ensure reliable and efficient fluid management, minimizing downtime and productivity.

3. Agricultural Spraying

- In agricultural settings, the FKB series pumps play a crucial role in pesticide and fertilizer spraying, providing the high-pressure output needed for uniform coverage and effective application.

- With their durable construction and versatile design, our pumps withstand the harsh conditions of agricultural operations, ensuring consistent performance season after season.

In conclusion, the FKB series represents a pinnacle of pumping technology, offering unmatched versatility, reliability, and performance across a wide range of applications. With their robust construction, efficient design, and flexible compatibility, these pumps are the ideal choice for demanding industrial environments. Trust in our FKB series pumps to deliver exceptional results, every time.

3-piston alternating volumetric pumps for use on cleaning units and industrial systems. It can be coupled to various types of motors, directly or with...

● FKB-N.1450rpm N version Ø24mm

| Model | FloW | Pressure | Power | Speed | Inlet | Outlet | Weight | |||

| L/min | gpm | bar | psi | hp | kw | rpm | thread | thread | KG | |

| FKB1835 | 18 | 4.7 | 350 | 5075 | 16.9 | 12.6 | 1450 | G3/4" | G3/8" | 16 |

| FKB2135 | 21 | 5.5 | 350 | 5075 | 19.7 | 14.7 | 1450 | G3/4" | G3/8" | 16 |

| FKB2925 | 29 | 7.7 | 250 | 3625 | 19.4 | 14.5 | 1450 | G3/4" | G3/8" | 16 |

| FKB4020 | 40 | 10.6 | 200 | 2900 | 21.3 | 16 | 1450 | G3/4" | G3/8" | 16 |

| FKB4520 | 45 | 11.9 | 200 | 2900 | 24.1 | 18 | 1450 | G3/4" | G3/8" | 16 |

Feike is a FKB Series Pump For Sale and Custom Nickel Pump in Taizhou, Zhejiang, China. We have high precision Automatic TAKAM CNC machines and 3D coordinate no-contact detection machine to ensure the quality of the Pump heads, Crankshaft cases, and valves for the pumps. We have 4 assembly lines so far. Three production lines for triplex pumps separated by high pressure, mid pressure, and low pressure. And one production line for safety valves and regulating valves. We use fixtures to ensure the assembly quality of the ceramic plungers. Air tightness testing is applied for every single semi-finished pump before injecting the lubrication oil.

And every single triplex plunger pump will be tested with an electric motor for running about 15 minutes before final packing. We use lasing to carve the ID numbers on the surface of the pump for tracking. Every final pump is packed with an air bag to protect the pump from damage in the transportation. We can produce about 6000 triplex plunger pumps a month. Welcome to inquiry about our products. We are looking forward to cooperating with you.

Introduction to Stainless Steel Pump Comparison A Stainless Steel Pump is widely used in industrial, chemical, and food ...

READ MOREIntroduction to Plunger Pump Selection A Plunger Pump is a type of positive displacement pump commonly used in high-pres...

READ MOREIntroduction to Fluid Compatibility A high-pressure pump is a critical component in various industrial and commercial sy...

READ MORE