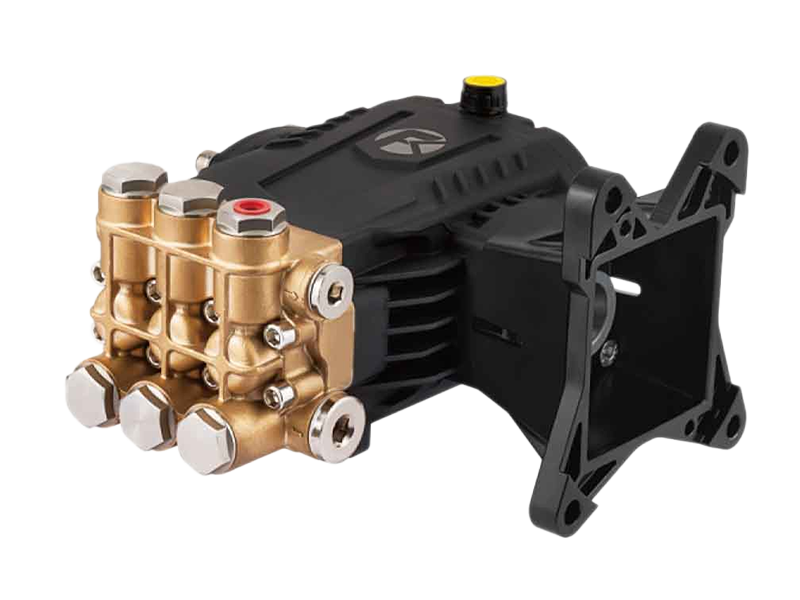

FKE-F04 Brass Regular Pump

3-piston alternating volumetric pumps for use on cleaning units and industrial systems. It can be coupled to various types of motors, directly or with...

Welcome to the FKE series, a premier line of 3-piston alternating volumetric pumps designed for high-performance use in cleaning units and various industrial systems. The FKE series represents the pinnacle of engineering excellence, providing robust, reliable, and efficient solutions for a wide range of applications. These pumps can be seamlessly coupled to different types of motors, either directly or via flexible joints, making them highly versatile and adaptable to numerous operational requirements.

Key Features

1. Superior Construction Materials

The FKE series pumps boast a pump body and cover made from die-cast aluminum alloy, ensuring a lightweight yet durable construction. This material choice provides resistance to corrosion and wear, extending the lifespan of the pumps even in demanding environments. Additionally, the rear cover is equipped with an oil drain outlet, and the side cover may either be blind or feature an oil sight glass, offering flexibility in monitoring and maintenance.

2. Advanced Piston and Rod Mechanism

The pistons in the FKE series are driven by a crank-connecting rod mechanism, which is a hallmark of precision engineering. The pump shaft is constructed from pressed high-strength steel, providing exceptional durability and resistance to stress. The connecting rods are made from a special low-friction zinc-aluminum alloy, die-cast to precise specifications to ensure minimal friction and efficiency. The one-piece ceramic pistons offer wear resistance and longevity, enhancing the overall performance of the pumps.

3. Efficient Sealing and Maintenance Design

A standout feature of the FKE series is its double gasket sealing system, which ensures a reliable and leak-proof operation. The pump head is made from pressed brass, known for its mechanical properties and corrosion resistance. The intake and delivery valves are designed with plugs, facilitating easier maintenance and reducing downtime. This thoughtful design feature allows for quick and straightforward servicing, ensuring that the pumps remain operational with minimal interruption.

Advantages

1. Exceptional Durability

The FKE series pumps are engineered for longevity. The use of high-strength materials like die-cast aluminum alloy for the body and cover, pressed high-strength steel for the shaft, and one-piece ceramic pistons ensures that these pumps can withstand rigorous use in industrial settings. The oversized friction bearings further enhance durability, providing smooth and reliable operation over extended periods.

2. High Efficiency and Performance

Efficiency is at the core of the FKE series design. The crank-connecting rod mechanism, combined with low-friction materials for the connecting rods and the advanced sealing system, ensures that the pumps operate with high efficiency. This leads to reduced energy consumption and lower operational costs, making the FKE series an economical choice for businesses.

3. Versatility and Adaptability

One of the key advantages of the FKE series is its versatility. These pumps can be coupled to various types of motors, either directly or with a flexible joint, allowing them to be integrated into a wide range of systems. This adaptability makes the FKE series suitable for diverse applications, from cleaning units to other industrial systems, providing a versatile solution that can meet different operational needs.

Applications

1. Cleaning Units

The FKE series pumps are ideal for use in cleaning units, where their robust construction and high efficiency can handle the rigorous demands of industrial cleaning. The ability to maintain consistent pressure and flow ensures effective and thorough cleaning, whether in automotive, manufacturing, or other industrial sectors.

2. Industrial Systems

Beyond cleaning units, the FKE series is suitable for various industrial systems that require reliable volumetric pumps. From water treatment facilities to chemical processing plants, the FKE series can deliver consistent performance and withstand the harsh conditions typical in these environments.

3. Custom Engineered Solutions

The flexibility of the FKE series allows for custom-engineered solutions tailored to specific industry needs. Whether requiring specific motor couplings or bespoke configurations, the FKE series can be adapted to meet unique operational requirements, providing a customized and effective pumping solution.

Conclusion

The FKE series of 3-piston alternating volumetric pumps stands as a testament to engineering and design. With their robust construction, advanced piston and rod mechanism, efficient sealing and maintenance features, the FKE series provides exceptional durability, high efficiency, and versatile application potential. Whether for cleaning units or a variety of industrial systems, the FKE series offers reliable, efficient, and adaptable solutions that meet the standards of performance. Invest in the FKE series pumps to ensure operation, reduced downtime, and long-term value for your industrial needs.

3-piston alternating volumetric pumps for use on cleaning units and industrial systems. It can be coupled to various types of motors, directly or with...

3-piston alternating volumetric pumps for use on cleaning units and industrial systems. It can be coupled to various types of motors, directly or with...

3-piston alternating volumetric pumps for use on cleaning units and industrial systems. It can be coupled to various types of motors, directly or with...

3-piston alternating volumetric pumps for use on cleaning units and industrial systems. It can be coupled to various types of motors, directly or with...

3-piston alternating volumetric pumps for use on cleaning units and industrial systems. It can be coupled to various types of motors, directly or with...

3-piston alternating volumetric pumps for use on cleaning units and industrial systems. It can be coupled to various types of motors, directly or with...

● FKE-F04.1450rpm C version Ø24mm

| Model | FloW | Pressure | Power | Speed | Inlet | Outlet | Weight | |||

| L/min | gpm | bar | psi | hp | kw | rpm | thread | thread | KG | |

| FKE0310 | 3.3 | 0.9 | 100 | 1450 | 1 | 0.75 | 1450 | G1/2" | G3/8' | 7.5 |

| FKE0610 | 5.5 | 1.45 | 100 | 1450 | 1.5 | 1.1 | 1450 | G1/2" | G3/8" | 7.5 |

| FKE0910 | 9 | 2.4 | 100 | 1450 | 2 | 1.5 | 1450 | G1/2" | G3/8" | 7.5 |

| FKE1115 | 11 | 2.9 | 150 | 2200 | 4 | 3 | 1450 | G1/2" | G3/8" | 7.8 |

● FKE-F05.1450rpm C version Ø28mm

| Model | FloW | Pressure | Power | Speed | Inlet | Outlet | Weight | |||

| L/min | gpm | bar | psi | hp | kw | rpm | thread | thread | KG | |

| FKE1325 | 13.2 | 3.5 | 250 | 3600 | 8.6 | 6.5 | 1450 | G1/2" | G3/8" | 7.6 |

| FKE1525 | 15.4 | 4 | 250 | 3600 | 10 | 7.5 | 1450 | G1/2" | G3/8" | 7.6 |

| FKE2010 | 20 | 5.3 | 100 | 1450 | 5.3 | 4 | 1450 | G1/2" | G3/8" | 7.6 |

| FKE2020 | 20 | 5.3 | 200 | 2900 | 10.6 | 8 | 1450 | G1/2" | G3/8' | 7.6 |

● FKE-F06.3440rpm C version Ø20mm

| Model | FloW | Pressure | Power | Speed | Inlet | Outlet | Weight | |||

| L/min | gpm | bar | psi | hp | kw | rpm | thread | thread | KG | |

| FKE1319 | 13 | 3.5 | 190 | 2755 | 6.5 | 4.8 | 3440 | G1/2" | G3/8" | 7.5 |

| FKE1615 | 16 | 4.3 | 150 | 2200 | 7 | 5 | 3440 | G1/2" | G3/8" | 7.5 |

| FKE1815 | 18 | 4.9 | 150 | 2200 | 7 | 5 | 3440 | G1/2" | G3/8" | 7.8 |

● FKE-F07.3440rpm C version Ø25.4mm

| Model | FloW | Pressure | Power | Speed | Inlet | Outlet | Weight | |||

| L/min | gpm | bar | psi | hp | kw | rpm | thread | thread | KG | |

| FKE1825 | 18 | 4.9 | 250 | 3600 | 13 | 9.8 | 3440 | G1/2" | G3/8" | 7.7 |

| FKE2420 | 24 | 6.4 | 200 | 2900 | 13 | 9.8 | 3440 | G1/2" | G3/8" | 7.7 |

● FKET-F05.1450rpm C version Ø24mm Ø28mm

| Model | FloW | Pressure | Power | Speed | Inlet | Outlet | Weight | |||

| L/min | gpm | bar | psi | hp | kw | rpm | thread | thread | KG | |

| FKET1110 | 11 | 2.9 | 100 | 1450 | 3 | 2.2 | 1450 | Φ19 | 18x1.5 | 7.8 |

| FKET1312 | 13 | 3.5 | 150 | 2200 | 5.5 | 4 | 1450 | Φ19 | G3/8" | 7.8 |

| FKET1315 | 13 | 3.5 | 150 | 2200 | 5.5 | 4 | 1450 | Φ19 | 22x1.5 | 7.8 |

| FKET1520 | 15.4 | 4 | 200 | 2900 | 7.5 | 5.5 | 1450 | Φ19 | 7.8 | |

● FKE-F11.1450rpm C version Ø28mm

| Model | FloW | Pressure | Power | Speed | Inlet | Outlet | Weight | |||

| L/min | gpm | bar | psi | hp | kw | rpm | thread | thread | KG | |

| FKE1325 | 13.2 | 3.5 | 250 | 3600 | 8.6 | 6.5 | 1450 | Φ19 | 18x1.5 | 9 |

| FKE1525 | 15.4 | 4 | 250 | 3600 | 10 | 7.5 | 1450 | Φ19 | G3/8" | 9 |

| FKE2010 | 20 | 5.3 | 100 | 1450 | 5.3 | 4 | 1450 | Φ19 | 22x1.5 | 9 |

| FKE2020 | 20 | 5.3 | 200 | 2900 | 10.6 | 8 | 1450 | Φ19 | 9 | |

| Model | FloW | Pressure | Power | Speed | Inlet | Outlet | Weight | |||

| L/min | gpm | bar | psi | hp | kw | rpm | thread | thread | KG | |

| FKER 0810 | 8 | 2.1 | 100 | 1450 | 2.2 | 1.6 | 1450 | G1/2" | G3/8" | 7.3 |

| FKER 1510 | 15.4 | 4 | 100 | 1450 | 4 | 3 | 1450 | G1/2" | G3/8" | 7.3 |

| FKER 1525 | 15.4 | 4 | 250 | 3600 | 10 | 7.5 | 1450 | G1/2" | G3/8" | 7.3 |

| Model | FloW | Pressure | Power | Speed | Inlet | Outlet | Weight | |||

| L/min | gpm | bar | psi | hp | kw | rpm | thread | thread | KG | |

| FKER 0810 | 8 | 2.1 | 100 | 1450 | 2.2 | 1.6 | 1450 | G1/2" | G3/8" | 7.3 |

| FKER 1510 | 15.4 | 4 | 100 | 1450 | 4 | 3 | 1450 | G1/2" | G3/8" | 7.3 |

| FKER 1525 | 15.4 | 4 | 250 | 3600 | 10 | 7.5 | 1450 | G1/2" | G3/8" | 7.3 |

Feike is a FKE Series Pumps Manufacturer and China Brass Pump in Taizhou, Zhejiang, China. We have high precision Automatic TAKAM CNC machines and 3D coordinate no-contact detection machine to ensure the quality of the Pump heads, Crankshaft cases, and valves for the pumps. We have 4 assembly lines so far. Three production lines for triplex pumps separated by high pressure, mid pressure, and low pressure. And one production line for safety valves and regulating valves. We use fixtures to ensure the assembly quality of the ceramic plungers. Air tightness testing is applied for every single semi-finished pump before injecting the lubrication oil.

And every single triplex plunger pump will be tested with an electric motor for running about 15 minutes before final packing. We use lasing to carve the ID numbers on the surface of the pump for tracking. Every final pump is packed with an air bag to protect the pump from damage in the transportation. We can produce about 6000 triplex plunger pumps a month. Welcome to inquiry about our products. We are looking forward to cooperating with you.

Introduction to Stainless Steel Pump Comparison A Stainless Steel Pump is widely used in industrial, chemical, and food ...

READ MOREIntroduction to Plunger Pump Selection A Plunger Pump is a type of positive displacement pump commonly used in high-pres...

READ MOREIntroduction to Fluid Compatibility A high-pressure pump is a critical component in various industrial and commercial sy...

READ MORE