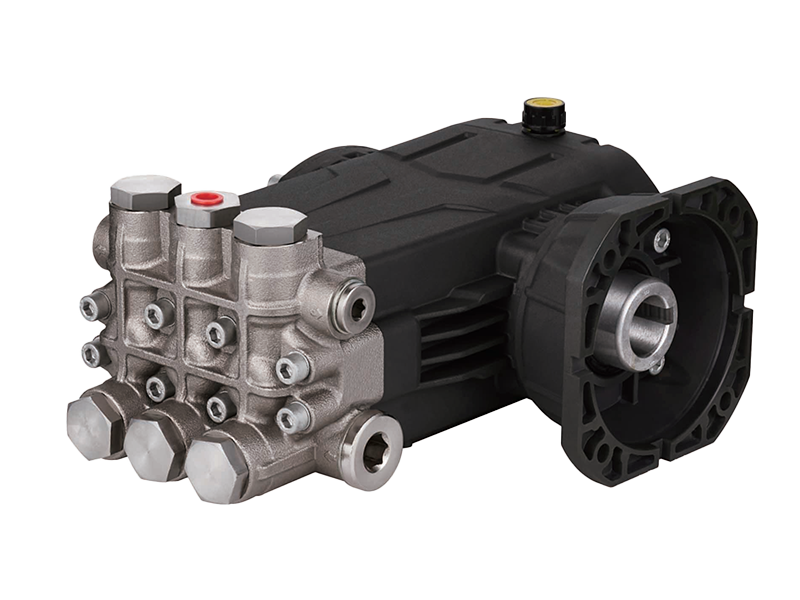

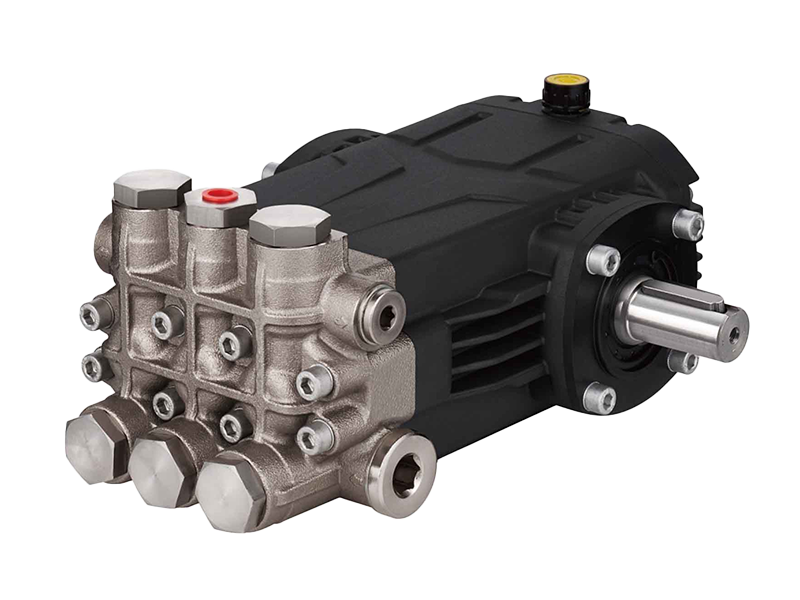

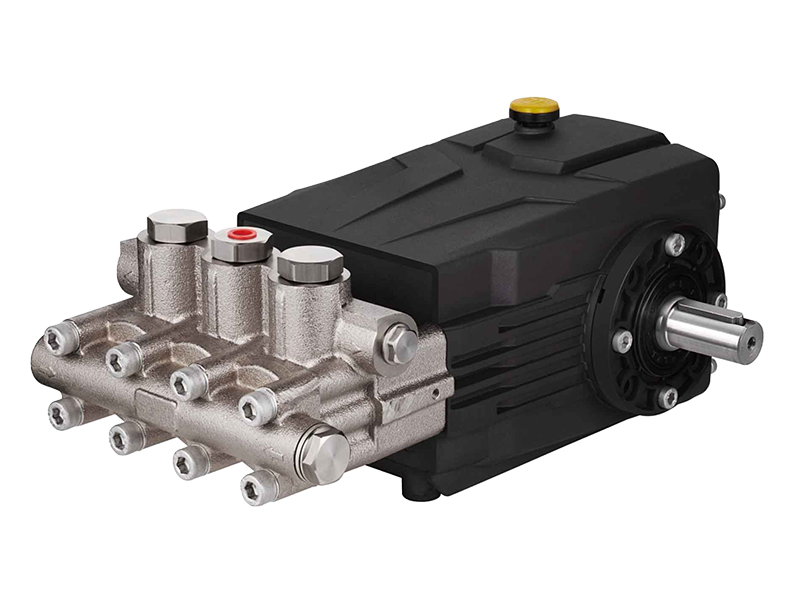

KTD-F01/F10 Cast iron nickel Pump

3-piston alternating volumetric pumps for use on cleaning units and industrial systems. It can be coupled to various types of motors, directly or with...

Our KTD Series represents a pinnacle of pumping excellence, meticulously crafted to meet the diverse needs of industries ranging from petroleum to food and pharmaceuticals. Engineered with precision and durability in mind, our KTD pumps deliver exceptional performance across a wide spectrum of applications.

Product Advantages:

- High Durability:

- Crafted from robust materials, our KTD pumps resist corrosion and wear, ensuring a long service life. With components made from durable stainless steel and cast copper, these pumps withstand harsh operating conditions.

- Reduced need for replacements translates to cost savings and uninterrupted operations, providing businesses with a reliable pumping solution that requires minimal maintenance.

- Superior Efficiency:

- Precision design and manufacturing optimize pump efficiency, resulting in energy savings and enhanced performance. Each component is carefully engineered to minimize energy consumption and maximize output.

- Maximum efficiency across various applications leads to improved productivity and reduced operational costs. Whether used in industrial processes or high-pressure cleaning tasks, our KTD pumps deliver consistent and efficient performance, contributing to overall cost savings for businesses.

- Versatile Applications:

- Suited for a wide range of industries including petroleum, chemical, food, and pharmaceuticals. From handling corrosive chemicals to transferring fluids in food processing, KTD pumps offer versatility and reliability in diverse environments.

- Ideal for high-pressure cleaning, descaling, and liquid production applications, offering versatility and adaptability. Whether used for cleaning industrial equipment or producing pharmaceutical liquids, KTD pumps excel in various applications, making them a valuable asset across industries.

Product Features:

- Advanced Design:

- Our KTD pumps boast an innovative design specifically crafted to effortlessly tackle demanding industrial processes.

- Through meticulous attention to detail, we minimize wear and tear, ensuring an extended operational lifespan for each pump.

- Precision Manufacturing:

- Every component undergoes precision manufacturing to maintain consistent quality and reliability in performance.

- By adhering to tight tolerances and utilizing top-notch materials, we guarantee functionality even in the harshest environments.

- Rigorous Quality Control:

- Our commitment to excellence is reflected in our rigorous quality control procedures, which include thorough inspections at every stage of production.

- These stringent measures ensure the reliability and performance of each pump, upholding our promise of delivering high-quality pumping solutions.

Product Applications:

- Essential in petroleum, chemical, and fertilizer industries as process pumps for fluid handling: Our KTD Series pumps play a vital role in facilitating fluid transfer and processing within the petroleum, chemical, and fertilizer sectors. Their robust construction and reliable performance ensure efficient operation in these demanding environments.

- Withstand rigorous demands of industrial applications, ensuring smooth operations: Designed to withstand the harsh conditions of industrial settings, our KTD pumps deliver consistent performance even under high pressures and abrasive fluids. Their durability and resilience guarantee uninterrupted operations, contributing to overall productivity.

In conclusion, our KTD Series stands as a testament to our commitment to providing high-quality, efficient, and reliable pumping solutions for diverse industries. With robust construction, precision manufacturing, and versatile applications, our KTD pumps offer unmatched performance and durability. Whether you require pumping solutions for industrial processes, cleaning tasks, or specialized applications, our KTD Series delivers unparalleled quality and performance. Experience the difference today and elevate your pumping operations to new heights with our KTD pumps.

3-piston alternating volumetric pumps for use on cleaning units and industrial systems. It can be coupled to various types of motors, directly or with...

3-piston alternating volumetric pumps for use on cleaning units and industrial systems. It can be coupled to various types of motors, directly or wit...

3-piston alternating volumetric pumps for use on cleaning units and industrial systems. It can be coupled to various types of motors, directly or wit...

3-piston alternating volumetric pumps for use on cleaning units and industrial systems. It can be coupled to various types of motors, directly or wit...

3-piston alternating volumetric pumps for use on cleaning units and industrial systems. It can be coupled to various types of motors, directly or wit...

● KTD-F01.1450rpm N version Ø28mm

| Model | FloW | Pressure | Power | Speed | Inlet | Outlet | Weight | |||

| L/min | gpm | bar | psi | hp | kw | rpm | thread | thread | KG | |

| FKD1530 | 15.4 | 4 | 300 | 4350 | 12 | 9 | 1450 | G1/2" | G3/8 | 11 |

| FKD2030 | 20 | 5.3 | 300 | 4350 | 16 | 12 | 1450 | G1/2" | G3/8" | 11 |

| FKD2610 | 26 | 6.9 | 100 | 1450 | 7.4 | 5.5 | 1450 | G3/4" | G3/8' | 11 |

| FKD3010 | 30 | 8 | 100 | 1450 | 8 | 6 | 1450 | G3/4" | G3/8" | 11 |

| FKD4010 | 40 | 10.5 | 100 | 1450 | 10 | 7.5 | 1450 | G3/4" | G3/8' | 11 |

● KTD-N.1450rpm N version Ø24mm

| Model | FloW | Pressure | Power | Speed | Inlet | Outlet | Weight | |||

| L/min | gpm | bar | psi | hp | kw | rpm | thread | thread | KG | |

| KTD1535 | 15.4 | 4 | 350 | 5075 | 14 | 10.5 | 1450 | G1/2" | G3/8" | 10.8 |

| KTD2035 | 20 | 5.3 | 350 | 5075 | 18.6 | 14 | 1450 | G1/2" | G3/8" | 10.8 |

| KTD2615 | 26 | 6.8 | 150 | 2200 | 10 | 7.5 | 1450 | G3/4" | G3/8" | 10.8 |

| KTD3015 | 30 | 7.9 | 150 | 2200 | 12 | 9 | 1450 | G3/4" | G3/8" | 10.8 |

| KTD4015 | 40 | 10.5 | 150 | 2200 | 16 | 12 | 1450 | G3/4" | G3/8" | 10.8 |

● KTA-N.1450rpm N version Ø24mm

| Model | FloW | Pressure | Power | Speed | Inlet | Outlet | Weight | |||

| L/min | gpm | bar | psi | hp | kw | rpm | thread | thread | KG | |

| KTA4020 | 40 | 10.6 | 200 | 2900 | 21.5 | 16 | 1450 | G1" | G1/2" | 19.5 |

| KTA5020 | 50 | 13.2 | 200 | 2900 | 36.5 | 20 | 1450 | G1" | G1/2" | 19.5 |

| KTA5215 | 52 | 13.7 | 150 | 2175 | 21 | 15.6 | 1450 | G1" | G1/2" | 19.5 |

| KTA5620 | 56 | 14.8 | 200 | 2900 | 30 | 22 | 1450 | G1" | G1/2" | 19.5 |

| KTA6615 | 66 | 17.5 | 150 | 2500 | 26.5 | 20 | 1450 | G1" | G1/2" | 19.5 |

| KTA7415 | 74 | 19.5 | 150 | 2200 | 30 | 22 | 1450 | G1" | G1/2" | 19.5 |

● KT-N.1450rpm N version Ø24mm

| Model | FloW | Pressure | Power | Speed | Inlet | Outlet | Weight | |||

| L/min | gpm | bar | psi | hp | kw | rpm | thread | thread | KG | |

| KT1250 | 12 | 3.2 | 500 | 7250 | 16 | 12 | 1450 | G1/2" | G3/8" | 20 |

| KT1650 | 16.5 | 4.4 | 500 | 7250 | 21.5 | 16 | 1450 | G1/2" | G3/8" | 20 |

| KT1850 | 18 | 4.8 | 500 | 7250 | 24 | 18 | 1450 | G1/2" | G3/8" | 20 |

| KT2335 | 23 | 6 | 350 | 5075 | 21.6 | 16.1 | 1450 | G1/2" | G3/8" | 20 |

| KT2250 | 22 | 5.8 | 500 | 7250 | 29.5 | 22 | 1450 | G1/2" | G3/2' | 20 |

| KT3050 | 30 | 8 | 500 | 7250 | 40 | 30 | 1450 | G1/2" | G3/8" | 20 |

● KTR-N.1450rpm N version Ø24mm

| Model | FloW | Pressure | Power | Speed | Inlet | Outlet | Weight | |||

| L/min | gpm | bar | psi | hp | kw | rpm | thread | thread | KG | |

| KTR1250 | 12 | 3.2 | 500 | 7250 | 16 | 12 | 1450 | G1/2" | G3/8" | 20.6 |

| KTR1650 | 16.5 | 4.4 | 500 | 7250 | 21.5 | 16 | 1450 | G1/2" | G3/8" | 20.6 |

| KTR1850 | 18 | 4.8 | 500 | 7250 | 24 | 18 | 1450 | G1/2" | G3/8" | 20.6 |

| KTR2335 | 23 | 6 | 350 | 5075 | 21.6 | 16.1 | 1450 | G1/2" | G3/8" | 20.6 |

| KTR2250 | 22 | 5.8 | 500 | 7250 | 29.5 | 22 | 1450 | G1/2" | G3/2' | 20.6 |

| KTR3050 | 30 | 8 | 500 | 7250 | 40 | 30 | 1450 | G1/2" | G3/8" | 20.6 |

Feike is a Sale KRD Series Pump and Custom Cast Iron Pump in Taizhou, Zhejiang, China. We have high precision Automatic TAKAM CNC machines and 3D coordinate no-contact detection machine to ensure the quality of the Pump heads, Crankshaft cases, and valves for the pumps. We have 4 assembly lines so far. Three production lines for triplex pumps separated by high pressure, mid pressure, and low pressure. And one production line for safety valves and regulating valves. We use fixtures to ensure the assembly quality of the ceramic plungers. Air tightness testing is applied for every single semi-finished pump before injecting the lubrication oil.

And every single triplex plunger pump will be tested with an electric motor for running about 15 minutes before final packing. We use lasing to carve the ID numbers on the surface of the pump for tracking. Every final pump is packed with an air bag to protect the pump from damage in the transportation. We can produce about 6000 triplex plunger pumps a month. Welcome to inquiry about our products. We are looking forward to cooperating with you.

Introduction to Stainless Steel Pump Comparison A Stainless Steel Pump is widely used in industrial, chemical, and food ...

READ MOREIntroduction to Plunger Pump Selection A Plunger Pump is a type of positive displacement pump commonly used in high-pres...

READ MOREIntroduction to Fluid Compatibility A high-pressure pump is a critical component in various industrial and commercial sy...

READ MORE